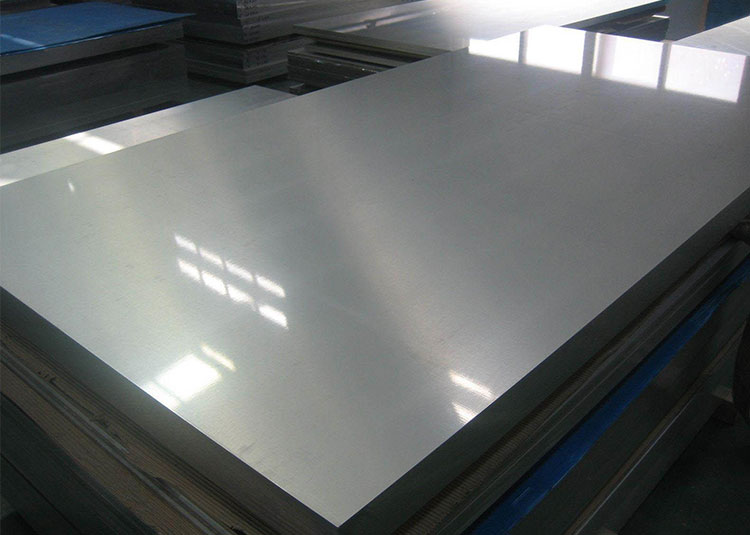

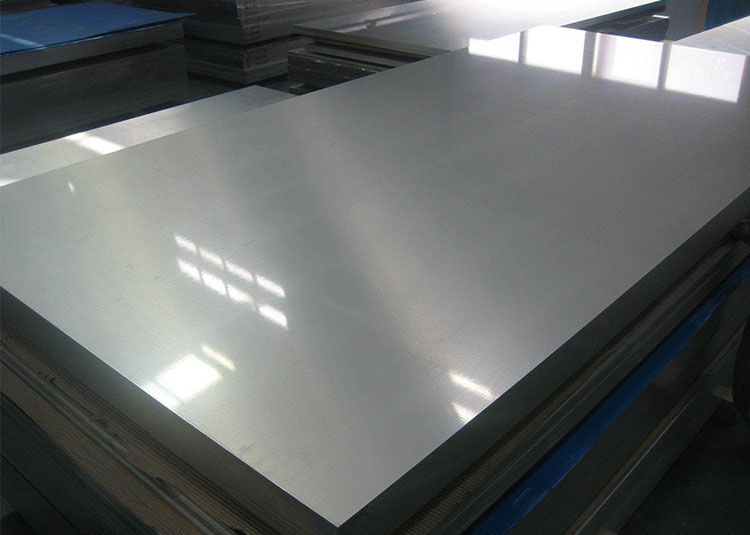

Wire drawing aluminium plate is a specialized aluminum product subjected to a controlled drawing process that imparts a distinct texture and enhanced surface properties. This treatment not only improves the mechanical characteristics of the aluminium plate but also lends excellent aesthetic appeal, making it popular across various industrial and decorative applications.

Introduction to Wire Drawing Aluminium Plate

Wire drawing aluminium plate is manufactured via a technique where the raw aluminium plate surface is mechanically brushed with fine abrasives or wire brushes, creating uniform, parallel lines on its surface. This process, also referred to as wire brushing or satin finishing, improves surface roughness, minimizes glare, and improves scratch resistance without compromising structural integrity.

Aluminium alloys typically used for wire drawing include both the 1000 series (pure aluminium) and 3000 series (aluminium-manganese alloys), selected for their excellent corrosion resistance, formability, and mechanical characteristics.

Features of Wire Drawing Aluminium Plate

| Feature | Description |

|---|---|

| Surface Texture | Distinctive fine parallel lines giving a satin or brushed appearance. |

| Scratch Resistance | Improved compared to polished plates due to textured surface. |

| Corrosion Resistance | Retains the inherent corrosion resistance of aluminium and its alloys. |

| Mechanical Properties | Maintains high tensile strength and ductility—good formability for further processing. |

| Anti-Glare Property | Reduced reflections and glare from light sources, enhancing visual comfort. |

| Thermal and Electrical Conductivity | Maintains high conductivity typical of aluminium. |

| Lightweight and Durable | Aluminium’s low density combined with augmented surface hold up under mechanical abrasion. |

Typical Chemical Composition of Common Aluminium Alloys Used

| Alloy Series | Major Elements | Typical Chemical Composition (wt.%) |

|---|---|---|

| 1000 Series | Aluminium (Al) | ≥ 99.0 % Al (99.00 - 99.90) |

| 3003 Alloy | Aluminium, Manganese (Mn) | Al: Balance, Mn: 1.0 - 1.5%, Cu ≤ 0.10%, Fe < 0.7% |

| 5052 Alloy | Aluminium, Magnesium (Mg), Chromium (Cr) | Al: Balance, Mg: 2.2 - 2.8%, Cr: 0.15 - 0.35%, Fe ≤ 0.4% |

The choice of alloy depends largely on the targeted properties such as strength, corrosion resistance, and weldability.

Common Applications of Wire Drawing Aluminium Plate

1. Architectural and Interior Design

- Used extensively in elevator panels, wall panels, and feature claddings.

- Popular for decorative ceilings and partitions due to its appealing surface finish and corrosion resistance.

- Applied in kitchens and cleanrooms where antibacterial and clean aesthetics are required.

2. Consumer Electronics and Appliances

- Wire drawing aluminium plates feature in laptop casings, mobile device covers, and other consumer electronics due to their lightweight and modern aesthetic.

- Appliance panels such as refrigerators, microwaves, and coffee machines frequently incorporate this material for enhanced scratch resistance and attractive finish.

3. Automotive Industry

- Interior trims and decorative moldings in vehicles are often manufactured from wire drawing aluminium to combine lightweight characteristics with abrasion resistance.

- Components requiring aluminum surfaces that resist clouds and fingerprint marks utilize this surface treatment.

4. Industrial Equipment

- Used to manufacture protective casing and machinery guard covers where durability and clean appearance help maintain professional industrial environments.

- Paneling in control rooms and factories benefits from the anti-glare properties.

5. Signage and Display

- Ideal for industrial nameplates, plaques, exhibition display panels, and commercial signage.

- The decorative surface and resistance to weather exposure support outdoor usage.

Advantages Compared to Other Surface Finishes

| Finish Type | Advantages | Limitations |

|---|---|---|

| Wire Drawing | Satin look, minimizes visible scratches, reduces glare, and maintains corrosion resistance. | Slightly less reflective. |

| Mirror Polished | High brightness, appeals in luxury products. | Prone to scratching and fingerprinting. |

| Anodized | Enhanced corrosion protection, variety of colors possible. | Often more expensive, and can obscure natural metal look. |