How to Choose Aluminous Buckle Ceiling: A Functional and Technical Guide

When it comes to modern interior design and architectural innovation, the aluminous buckle ceiling stands out as a versatile solution that blends aesthetics with functionality. But choosing the right aluminous buckle ceiling shouldn’t be a mere style-driven choice; its technical aspects and applications ensures you get the optimal performance and durability tailored to your space’s specific needs.

What Is an Aluminous Buckle Ceiling?

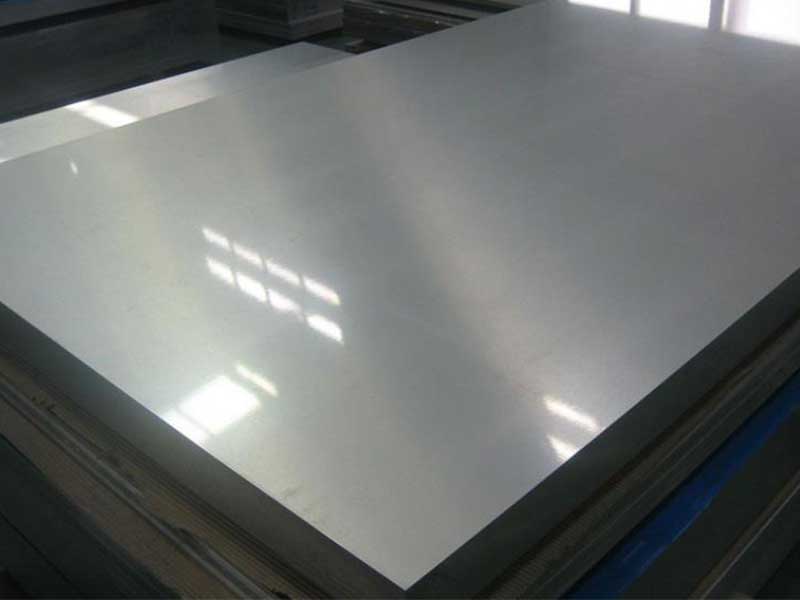

Fundamentally, an aluminous buckle ceiling consists of interlocking aluminum panels that form a sleek, seamless ceiling surface. Renowned for its lightweight, corrosion resistance, and fireproof features, aluminum makes an impeccable base for these ceiling panels. The “buckle” mechanism refers to the unique clasping system that secures panels tightly, offering uniformity and stability without visible screws or molds—a vital feature for clean and modern ceiling designs.

Functional Attributes to Consider

Durability and Resistance: Aluminum naturally resists rust and corrosion, but pay attention to surface treatments such as PVDF coating or anodization. PVDF coatings improve UV and weather resistance, which is especially important in humid or outdoor environments. Anodized finishes add durability and an attractive, metallic sheen.

Fire Resistance: Most aluminous buckle ceilings comply with Class A fire ratings, making them suitable for commercial buildings, hotels, and other public spaces that require stringent fire codes. Verifying compliance with local fire safety standards is essential.

Acoustic Performance: Today’s aluminum buckle ceilings often incorporate perforations or special backing materials to enhance sound absorption. If sound control is pivotal—for offices, conference rooms, or theatres—opt for panels designed with these acoustic properties.

Thermal Conductivity and Heat Dissipation: Aluminum’s high thermal conductivity can assist in passive heat dissipation, contributing to room temperature regulation in high-tech buildings. This attribute ensures your ceiling installation is not just decorative but also functional in managing indoor climate.

Technically Selecting Your Aluminous Buckle Ceiling

Choosing the proper thickness of aluminum is crucial. Standard aluminium sheet thickness ranges from 0.5mm to 1.2mm, with thicker panels offering longer lifespan but greater weight. The buckle system’s design compatibility also matters—the prototypical shoulder width, snap-in depth, and panel size should align with your architectural plans to facilitate smooth installation.

Additionally, consider the integration potential with LED lighting and HVAC diffusers. Some aluminous ceilings permit ease will of channeling wiring and vents within the gap spaces created by buckle joints, simplifying maintenance.

Applications that Benefit from Aluminous Buckle Ceilings

- Commercial and Retail Spaces: The sleek brushed or mirror-like finishes complement minimalistic interiors while ensuring easy emergency maintenance access due to snap-locking mechanisms.

- Transportation Hubs: Airports and metro stations exploit the metal ceiling’s robustness and fire resistance – areas exposed to frequent foot traffic and environmental stress.

- Exhibition Centers and Museums: Its smooth uninterrupted underside conceals overhead utilities elegantly while absorbing ambient sound vibrations particularly with acoustic variants.

- Outdoor or Semi-Outdoor Areas: With adequate surface coating, aluminous buckle ceilings withstand moisture better than traditional materials, Primavera patios or walkways.