3005 is an aluminum–manganese (Al–Mn) wrought alloy commonly used for corrosion-resistant, moderate-strength sheet products. Temper H14 indicates a strain-hardened condition with partial hardening (approximately 1/4 hard) achieved by cold working; it provides a balance of strength, formability and surface finish. The specified thicknesses (0.1, 0.2, 0.3, 0.5 mm) are typical for thin sheet applications such as decorative facings, cladding, light-weight housings, and heat-exchange fins.

features:

- Good corrosion resistance (atmospheric and many mildly corrosive environments)

- Good workability and moderate strength in H14 temper

- Excellent surface finish, suitable for coating and painting

- Good brazing and welding compatibility with common techniques

- Widely available in coils and cut-to-length sheets

Chemical Composition (typical, wt%)

| Element | Specification (%) |

|---|---|

| Al | Balance (≥ 96.7) |

| Mn | 1.0 – 1.5 |

| Fe | ≤ 0.7 |

| Si | ≤ 0.6 |

| Cu | ≤ 0.20 |

| Zn | ≤ 0.25 |

| Mg | ≤ 0.10 |

| Cr | ≤ 0.20 |

| Ti | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

Notes:

- Values given are typical limits per common standards (e.g., ASTM B209 / EN 573 / EN 485 derived guidance). Actual chemical certificates will be provided with each lot.

Mechanical Properties (H14 temper, typical)

| Property | Unit | Typical Value |

|---|---|---|

| Tensile strength (Rm) | MPa | 115 – 165 |

| Yield strength (Rp0.2) | MPa | 70 – 120 |

| Elongation (A50) | % | 2 – 8 (thickness dependent) |

| Hardness (HB) | HB | ~30 – 45 |

Notes:

- Mechanical properties vary with thickness and degree of cold work. Thinner gauges and higher cold work typically yield higher strength and lower elongation.

- Values above are typical ranges for 3005-H14 thin sheet; exact test values are supplied by the mill’s certificate of conformity.

Physical Properties

| Property | Unit | Value |

|---|---|---|

| Density | g/cm³ | 2.70 |

| Melting range | °C | 600 – 650 |

| Thermal conductivity (room temp) | W/m·K | ~150 – 160 |

| Electrical conductivity | % IACS | ~34 – 36 |

| Coefficient of thermal expansion | 10^-6 /°C | ~23.5 |

Available Dimensions and Tolerances

| Thickness (mm) | Typical Widths (mm) | Typical Lengths / Form | Thickness Tolerance (typical) |

|---|---|---|---|

| 0.10 | 100 – 1600 (coils/strips) | Coils / cut strips | ±0.01 – ±0.02 |

| 0.20 | 100 – 1600 | Coils / sheets | ±0.01 – ±0.02 |

| 0.30 | 100 – 1600 | Coils / sheets | ±0.02 – ±0.03 |

| 0.50 | 200 – 1600 | Coils / sheets / cut-to-length | ±0.02 – ±0.05 |

Notes:

- Width and length capability depends on mill and slitting/cutting equipment. Custom widths, edge trims, and tolerances available on request.

- Coil weights and maximum widths vary by producer. Typical coil ID/OD and packing details will be provided with the quotation.

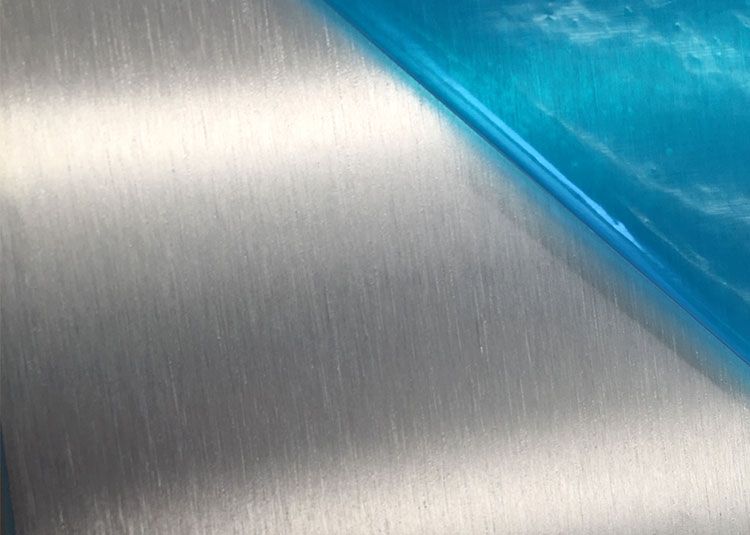

Surface Finishes & Coatings

| Finish Type | Description / Use |

|---|---|

| Mill finish (bright) | Standard smooth surface; suitable for painting, anodizing and laminating. |

| Anodized | Improved corrosion resistance, appearance and surface hardness; common for architectural trims. |

| PVDF / Polyester paint | Long-term color retention and weatherability (architectural cladding). |

| Stucco-embossed | Reduced reflectivity, improved stiffness and appearance for facings and panels. |

| Protective film | Applied for transport/processing protection on thin gauges. |

Formability & Fabrication

Cold forming:

- 3005-H14 provides good formability for bending, light drawing and profiling; radius recommendations depend on thickness and desired springback.

- For 0.1–0.3 mm gauges, tight radius bending is possible, but watch for edge cracking if excessive deformation or poor tooling is used.

Welding & Joining:

- Compatible with MIG, TIG and resistance spot welding. Pre- and post-weld cleaning recommended for optimal strength and appearance.

- Brazing and soldering compatible; use appropriate fluxes for Al–Mn alloys.

Cutting & Punching:

- Laser cutting, shearing, slitting and fine punching are all suitable for these thin gauges. Burr formation and edge rollover must be considered for final assembly.

Surface treatment:

- Good adherence for adhesives, paints, and anodizing with standard pre-treatment (degreasing, etching, desmutting).

Corrosion Resistance

- Excellent resistance to atmospheric corrosion and mild chemical environments due to the absence of copper and presence of manganese.

- Not suitable for marine environments with direct saltwater spray without protective coatings — consider additional coatings or marine-specific alloys for long-term exposure.

- Good performance for architectural cladding, appliance panels, furniture, and indoor environments.

Typical Applications

| Application Area | Examples & Advantages |

|---|---|

| Architectural | Interior/exterior cladding panels, facades (with coatings), soffits, trims — lightweight, good appearance, easy fabrication. |

| Decorative & signage | Painted or anodized thin panels for signs, nameplates, decorative facings — good surface finish and paint adherence. |

| Consumer goods | Appliance panels, housings, lamp reflectors — corrosion resistance and aesthetic finish. |

| HVAC & heat exchange | Fins and thin elements — good thermal conductivity and formability. |

| Packaging & lamination | Specialty packaging components, laminates and foils where moderate strength and corrosion resistance are needed. |

| Automotive (non-structural) | Trim, interior panels — light-weight and corrosion resistant. |

| Electronics & electrical | Light enclosures, shield panels — conductive and thermally conductive where needed. |

Handling, Storage & Quality Assurance

Handling:

- Use protective gloves to avoid fingerprints and surface blemishes.

- Avoid contact with dissimilar metals and corrosive contaminants during storage and processing.

Storage:

- Store in dry, ventilated areas on clean pallets or racks. Keep protective film intact until processing to avoid scratching.

Quality assurance:

- Mill certificates (chemical and mechanical) provided with each lot.

- Dimensional inspection and surface quality checks available per order.

- Traceability to production batch and heat number on request.

Ordering Information & Options

Common order options:

- Thickness: 0.10, 0.20, 0.30, 0.50 mm

- Temper: H14 (other tempers possible on request)

- Widths: custom slit widths up to mill maximum

- Lengths: coils or cut-to-length sheets

- Surface finish: mill, anodized, painted, protective film

- Edge type: trimmed, slit, mill edge

When ordering, provide:

- Required thickness, width and length (or coil vs. sheet)

- Surface finish and coating requirements

- Quantity and delivery schedule

- Any special testing or certification requirements (e.g., material test report, third-party inspection)

Aluminum sheet 3005 H14 in thin gauges (0.1, 0.2, 0.3, 0.5 mm) is a versatile, corrosion-resistant material well-suited to decorative, architectural, HVAC and consumer product applications. It offers a favorable combination of surface finish, formability and moderate strength. For quotation and supply, specify dimensions, surface treatments and any certification needs; technical assistance is available for forming radii, joining methods and finish selection.