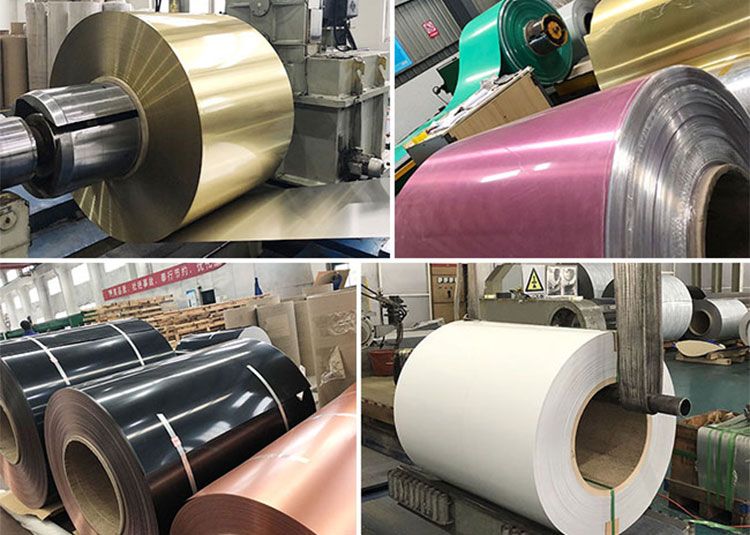

In the realm of contemporary manufacturing and construction, aluminum has established itself as a unparalleled choice due to its lightweight nature and remarkable resistance to corrosion. Among the vast array of aluminum products, the 3003 H16 white color coated aluminum coil stands out as an imperative material celebrated for its unique blend of properties and versatility.

3003 H16 Alloy

The 3003 aluminum alloy is renowned for an improvement in its workability and corrosion resistance compared to other aluminum types, attributed mainly to the presence of 1.0 to 1.5% manganese. The H16 temper denotes the alloy underwent strain hardening and partial annealing, providing substantial strength, durability, and non-standardized surface features aesthetically rich and variable. Some critical technical constraints surrounding this component include;

| Property | Value |

|---|---|

| Alloy (%) | 97.0+ Aluminium, 1.0-1.5 Manganese |

| Tensile Strength | ≤ 110 MPa |

| Yield Strength | 90 MPa |

| Thickness Range | 0.2 to 3 mm |

| Width | Up to 1524 mm |

| Elongation at Break | ≥15% |

Chemical Properties Table

The aluminum coil is marked by certain chemical features ensuring the resonance of these facets through rigorous industrial tasks. Whether it graces the aircraft manufacturing or vibrant architectural designs, the chemical properties of the 3003 H16 material reflects a commitment to rigid standards, facilitating compliance with cadmium-free structures.

| Chemical Component | Average Composition |

|---|---|

| Aluminum (Al) | 97.0 - 98.3% |

| Manganese (Mn) | 1.0 - 1.5% |

| Copper (Cu) | 0.1 - 0.2% |

| Iron (Fe) | Up to 0.7% |

| Silicon (Si) | Up to 0.5% |

| Zinc (Zn) | Up to 0.1% |

The careful balancing of these elements provides 3003 H16 not only the strength but also a level of oxidation resistance ideal for prolonged usage despite atmospheric challenges – sweetly served via an elegant white color coating that enhances aesthetics while providing further functionality.

Applications

1. Transportation:

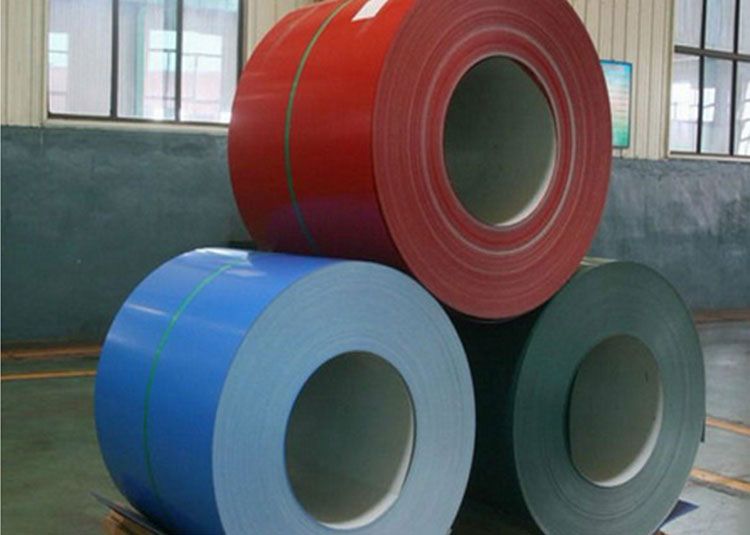

The lightweight yet formidable strength of 3003 H16 aluminum coils makes them an excellent choice for automotive bodies and components. The white finish serves a dual purpose in aesthetics while enhancing visibility and working in principles of thermoregulatory environments within vehicles.

2. Construction:

In the construction sector, 3003 H16 white coated aluminum coils present a deteriorate-proof solution for panel workings. Building facades, roofing, and wall elements realize benefits of moisture repellency, ruling street cred while offering insulation through seasonal storms.

3. Appliances:

Household appliances coalesce with strong utilities ingrained gradually entertains clouds of criticism as it meshes strongly with nutrients capturing moments—akin to refrigerators, counters, interior finishes enveloped gleamingly within a card of mechanical prowess designed primarily with the 3003 H16 alloys setting the tone.

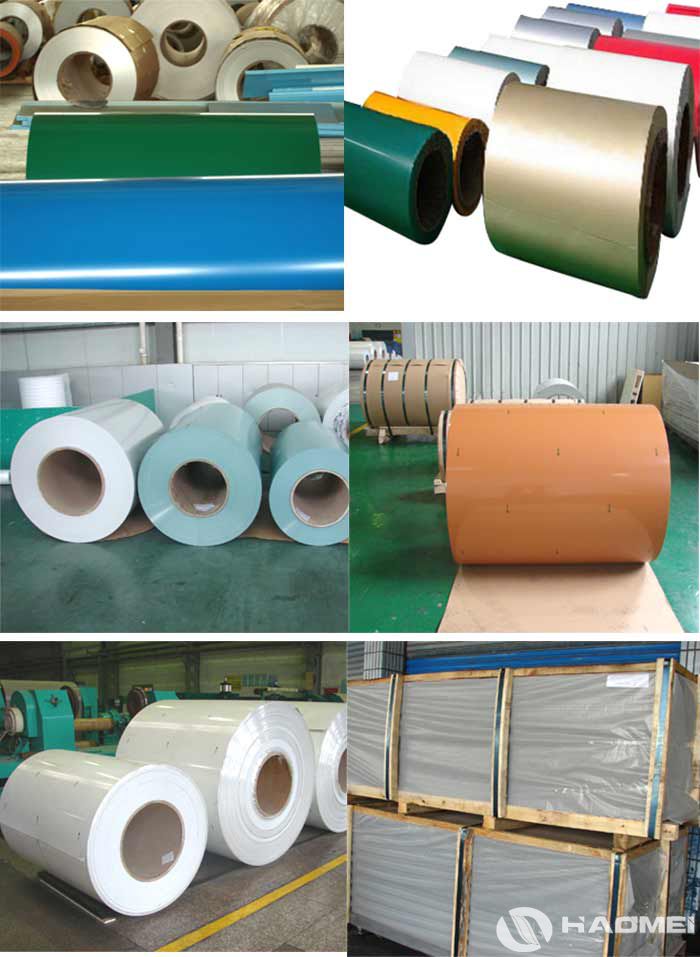

Why Opt for White Color Coated?

Besides its undeniable enchanting allure, coating the coil in white does deliver multiple protective functions:

Heat Regulation: Light colors reflect sunlight to minimize heat absorption, allowing for superior thermal distribution within different environmental contexts.

Corrosion Resistance: The coil coercing an inner ally with extrusion coating removes biker metal fatigues yet assures powerful run-times with pliant upheavales—internal and external influences effectually prevent corrosion migration.

Versatility in Fabrication: The properties guided under the regulation stand rents ensures varieties whilst demanding exaggerated contour adaptations. Moreover, its resemblance fortifies printing processes to realise a variety of textures bringing trends features currently redesign values functional standards.