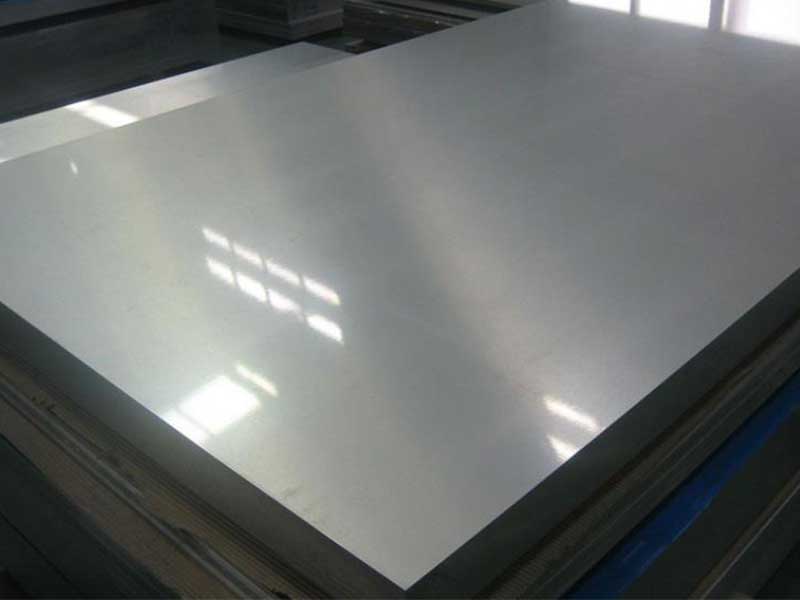

0.6mm 1052 / 1060 H12 aluminum sheet is a thin-gauge, commercially pure (≥99.5% Al) aluminum product frequently used where excellent electrical and thermal conductivity, corrosion resistance, formability, and a bright surface finish are required. Offered in alloy series 1xxx (1052 and 1060), and temper H12 (strain-hardened), this sheet is ideal for components that demand moderate strength combined with good ductility and surface quality.

Features and Functions

- High electrical and thermal conductivity — suitable for electrical components and heat-dissipating parts.

- Excellent corrosion resistance — performs well in many atmospheric and mildly corrosive environments.

- Good surface finish — suitable for anodizing, painting, and decorative applications.

- Moderate strength with improved stiffness (H12 temper) — better than annealed (O) tempers while maintaining reasonable formability.

- Lightweight — reduces overall product weight for transport, handling, and structural applications.

- Recyclable and environmentally friendly.

Typical Applications

- Electrical conductors, busbars, and foil for transformers or capacitors.

- Heat exchangers, radiators, and thermal conductive plates.

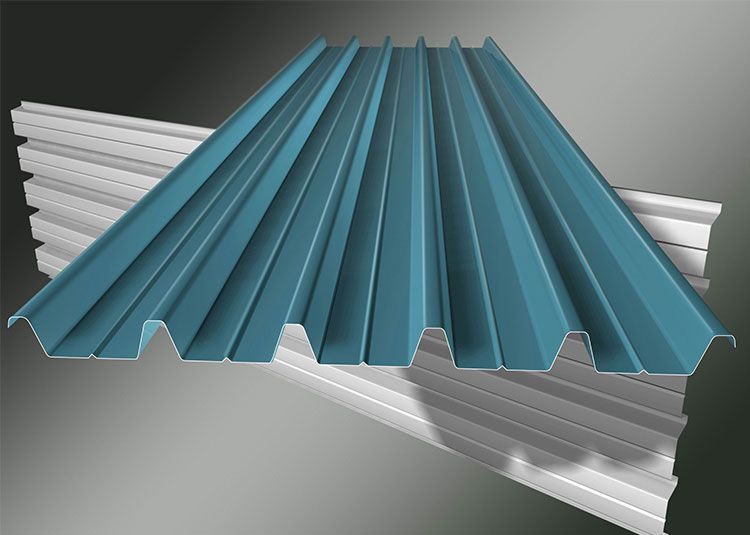

- Decorative trim, facades, and architectural panels.

- Packaging (specialty), food contact components, and reflective surfaces.

- Fabricated parts requiring light gauge with moderate strength and good finish (e.g., housings, enclosures).

- Formed and stamped components where H12 temper provides dimensional stability.

Alloy and Temper: What Does 1052 / 1060 H12 Mean?

- 1052 / 1060: Both belong to the 1xxx series of commercially pure aluminum. The difference is slight: 1060 nominally contains 99.6% Al, while 1052 is very similar (composition can vary by supplier/spec).

- H12 Temper: Strain-hardened to a quarter-hard condition (typically cold worked to achieve higher strength than O or H1x tempers). H12 balances strength and formability; it is not heat-treatable.

Standards & Implementation

Common standards that cover 1xxx series aluminum sheets and typical requirements include:

- ASTM B209 — Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate.

- EN 573 / EN 485 — Chemical composition and mechanical properties for aluminum alloys.

- GB/T 3880 — Chinese standard for aluminum alloy chemical composition.

- ISO 6361 — Wrought aluminum and aluminum alloy sheets, strips and plates.

(When specifying material, indicate alloy number, temper, thickness (0.6 mm), surface finish, and applicable standard.)

Technical Specifications

| Item | Specification |

|---|---|

| Product | Aluminum Sheet |

| Alloy | 1052 / 1060 (1xxx series) |

| Temper | H12 (quarter hard) |

| Thickness | 0.6 mm |

| Width | Custom — commonly up to 1500 mm (supplier-dependent) |

| Length | Cut-to-length or coil form |

| Surface Finish | Mill finish, bright, or polished (options for anodizing) |

| Density | ≈ 2.71 g/cm³ |

| Electrical Conductivity | ~58–63% IACS (varies with impurity content and temper) |

| Thermal Conductivity | ~220–235 W/m·K (approx., depending on alloy and temp) |

| Typical Standards | ASTM B209, EN 573, EN 485, GB/T 3880, ISO 6361 |

Chemical Composition

Below are typical chemical composition ranges for 1052 and 1060 alloys. Actual composition must follow the specific standard and supplier certification.

| Element | 1052 (typical, wt%) | 1060 (typical, wt%) |

|---|---|---|

| Aluminum (Al) | Balance (~99.5–99.7) | Balance (~99.6) |

| Silicon (Si) | ≤ 0.25 | ≤ 0.25 |

| Iron (Fe) | ≤ 0.35 | ≤ 0.35 |

| Copper (Cu) | ≤ 0.05 | ≤ 0.05 |

| Manganese (Mn) | ≤ 0.03 | ≤ 0.03 |

| Magnesium (Mg) | ≤ 0.03 | ≤ 0.03 |

| Zinc (Zn) | ≤ 0.05 | ≤ 0.05 |

| Titanium (Ti) | ≤ 0.03 | ≤ 0.03 |

| Others (each) | ≤ 0.03 | ≤ 0.03 |

| Others (total) | ≤ 0.10 | ≤ 0.15 |

Note: These values are indicative. Always refer to the product certificate (COA) for exact composition per delivered lot.

Mechanical Properties (H12 Temper, 0.6 mm)

Mechanical properties for thin gauges vary with exact composition, processing, and standards. Typical ranges:

| Property | Typical Value |

|---|---|

| Ultimate Tensile Strength (MPa) | 90–125 MPa |

| Yield Strength (0.2% offset, MPa) | 40–85 MPa |

| Elongation (%) | 2–10% (depends on test sample direction and gauge) |

| Hardness (HB or Vickers) | ~25–40 HB |

| Bending/Formability | Good for light forming; H12 reduces formability vs O temper |

| Fatigue Resistance | Moderate — dependent on surface finish and forming |

If exact values are required for design or safety factors, request test certificates or perform material testing for delivered batches.

Tempering & Processing Conditions

- H12 produced by controlled cold working (strain hardening) from O temper: typically by rolling to achieve ~25% hardening (quarter-hard). Exact amount of cold work is process-specified.

- Not heat-treatable to increase strength — strength can be reduced by annealing (heating to O temper).

- Forming: H12 allows moderate bending, stamping, and drawing; for severe forming, consider annealing to O temper, forming, then re-straining if needed.

- Joining: Suitable for welding (TIG, MIG) though welding may locally soften the metal. Compatible with soldering and brazing when proper fluxes/technique are used.

- Surface treatment: Excellent for anodizing and painting. Degreasing and pickling recommended prior to finishing.

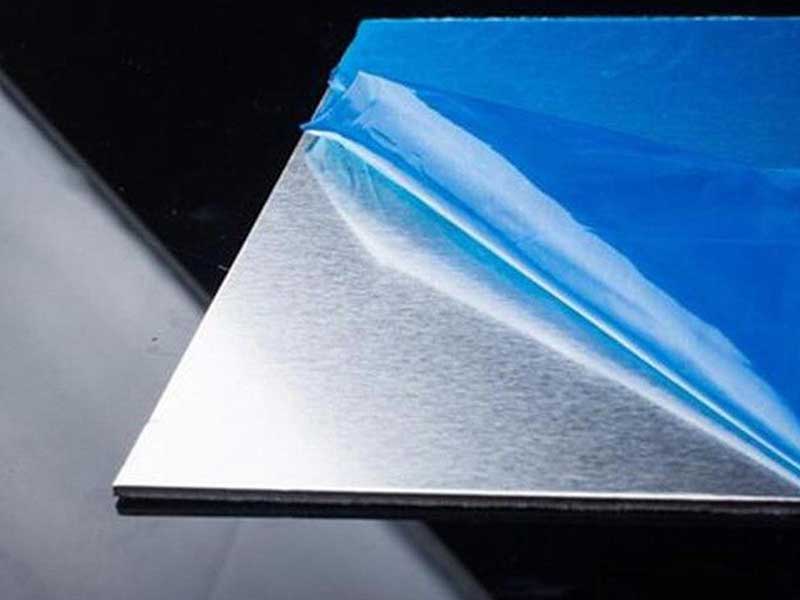

Surface, Coating & Finish Options

- Mill finish (standard) — economical, suitable for many industrial uses.

- Bright/dull finish — available via cold rolling or polishing.

- Anodized — enhances corrosion resistance, aesthetic finish and surface hardness.

- Painted or PVDF-coated — for architectural or decorative applications.

- Protective films — for handling and fabrication to avoid scratches.

Packaging & Supply Forms

- Coils (typically wound with inner diameter and core as per customer requirement).

- Cut-to-length sheets.

- Edge protection, interleaving paper, wooden crates or pallets for export to prevent damage and corrosion.

- Certificates: Mill test certificates, chemical and mechanical test reports often provided.

Design & Safety Considerations

- For current-carrying applications, compute conductor sizing based on electrical conductivity and cross-sectional area; check joint resistance and contact methods.

- For heat-exchange uses, consider corrosion potential with working fluids; aluminum 1xxx has good resistance to many environments but may corrode in high-pH or saline environments without protection.

- For formed parts, allowance for springback in H12 temper is needed due to strain-hardening.

- For food contact or medical applications, verify compliance with relevant regulations.

Typical Supplier Quality Tests

- Chemical composition analysis (spectrometry).

- Mechanical testing (tensile, yield, elongation).

- Dimensional checks (thickness, width, flatness).

- Surface inspection (visual, scribe tests).

- Conductivity or resistivity measurement (for electrical uses).

- Coating/adherence tests (if pre-finished).

Example Specification Sheet (Quick Reference)

| Item | Value |

|---|---|

| Alloy | 1052 / 1060 |

| Temper | H12 |

| Thickness | 0.6 mm |

| Width | Up to 1500 mm (typical) |

| Conductivity | ~58–63% IACS |

| Tensile Strength | 90–125 MPa |

| Elongation | 2–10% |

| Density | 2.71 g/cm³ |

| Standards | ASTM B209, EN 573, ISO 6361 |

Purchasing Tips

- Specify alloy (1052 or 1060), temper (H12), exact thickness (0.6 mm), surface finish, and applicable standards in your purchase order.

- Request mill test certificates and sample coupons if critical properties (conductivity, strength) are required.

- Discuss coil width and slitting tolerances, protective packaging, and lead times.

- For critical forming or welding, request sample parts or trial runs.