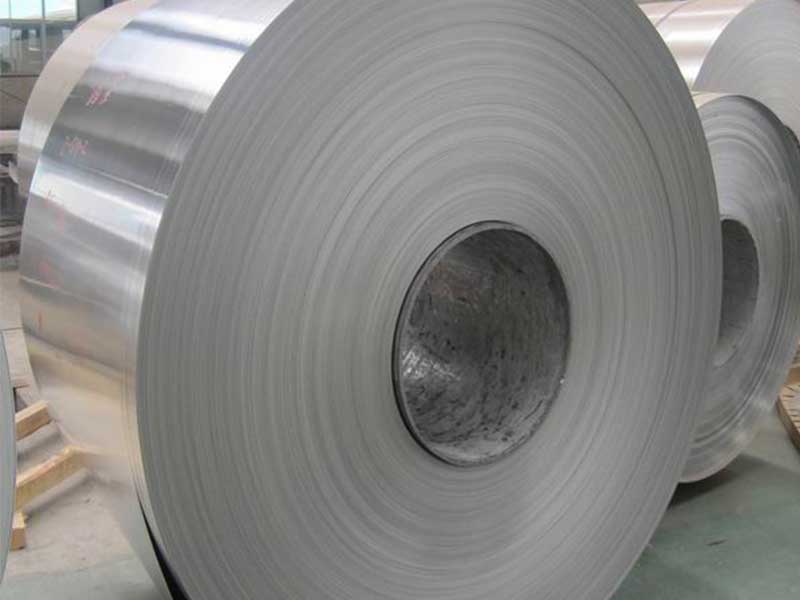

The realm of aluminum alloys provides diverse options for various applications, with the 3000 Series Aluminum Coil standing out particularly for its strong functionality, versatility, and efficiency.

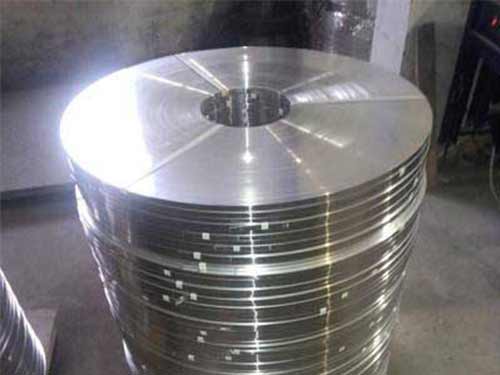

the 3000 Series Aluminum Strip

The 3000 series of aluminum akin to well-tuned instruments exhibit exceptional balance among strength, flexible manufacturing, and corrosion resistance. The pivotal constituent of the 3000 series aluminum is manganese, which gives this alloy group their unique identity. Specifically, 3003 aluminum coil is the most widely used variant globally, primarily due to its high functionality at economical costs.

Technical Properties: Table of Chemical Composition and Properties

| Parameter | Value/Specification |

|---|---|

| Alloy Designation | 3000 Series (e.g., 3003) |

| Chemical Composition | Manganese (Mn) ~ 1.0–1.5% |

| Aluminum (Al) ~ balance (min 97%) | |

| Copper (Cu), Magnesium (Mg) ~ including 0.2% ~ 0.7% | |

| Ultimate Tensile Strength | 110 - 215 MPa |

| Yield Strength | 55 - 130 MPa |

| Elongation % | 13%-35% (dependent on temper) |

| Density | 2.73 g/cm³ |

| Electrical Conductivity | Approximately 40% IACS |

| Corrosion Resistance | Excellent |

Norms & Implementation Standards: Guiding the Usage of Aluminum Strip

Navigating the implementation of the 3000 series aluminum strips require adherence to set norms and standards within the aluminum industry. The aluminum strips are produced worldwide per strict normative guidelines such as:

ASTM B241/B241M: These standards pertain to the performance and safety of aluminum and aluminum alloy strips orchestrating mechanical properties.

AS/NZS 1734/3: This standard introduces aluminum sheets and strips, nurturing good structural behavior against decay and corrosion.

EU RoHS Compliant: Confirming minimum harmful material limitations and ensuring ecological responsibility in viable industries.

Functions of the 3000 Series Aluminum Coil

The robust formulation manifested through high-density manganese results in several esteemed functions:

Corrosion Resistance: Thus implying extended longevity, primarily because the non-heat-treatable attributes finely to oxidization through pristine aluminum layer formation.

Formability and Fabrication: Promises exceedingly good workability making them conducive in bending and forming processes. Forging custom products for discerning needs elevates options drastically.

High Thermal and Electrical Conductivity: Purposed extensively in applications like heat exchangers, capacitors, etc. The strip readily loses or collects heat culminating both residential and industrial problems.

Applications Across Industries: A Blend of Necessity and Innovation

Automotive Industry: Aluminum strip from the 3000 series powers undercarriage components allowing seamless integration, creating lightweight models to improve efficiency and reduce emissions. Its ROI compounds over years while anodization presents distort-free surfaces.

Beverage Cans and Food Packaging: End-uses thrive predominantly embossed with printed designs encapsulating those aluminum cans we so frequently see in stacks. Superiority reflected for overcoming plate-it impact stress leads directly to trustworthy product showcase.

Lightning, Signage, and Thermoelectric Modules: The 3003 colors composure vis-à-vis attributes in sharp corrosion-opped applications proceed within signage presentations impeccably, reflective tag properties personalized through adaptable images ganaches stringent aesthetics with quantum-smooth coatings also reflecting non-failure scenarios within thermodynamic equations.

Construction and Facade Work: In collections, where the appearance necessity amalgamates together the strength of form, façades frames upstairs earn bragging rights contributed hence from quality 3000 foiled aluminum strapping, painting lives with zest while encouraging moisture defense from whims, propelled Legion tô.-form benefit environments apart phrases and certifications.