Aluminum has held a pivotal role in a myriad of applications over the decades—its lightweight, corrosion-resistant, and conductive properties serve various industries well. A notable application of aluminum is in the electrical sector, specifically regarding cables where shielding plays a crucial role. Among the various aluminum alloy grades, 1235 and 8011 possess unique attributes that make them ideal choices for cable wrapping, particularly when heavy-duty shielding is required for power grid cables.

The Critical Role of Heavy Duty Shielding

The stability of power supply systems rests significantly on the quality of its materials—especially concerning cable integrity. Heavy duty shielding acts as a protective layer to underlying components, ensuring the insulated and conductive sections do not deteriorate under environmental stressors like temperature fluctuations, moisture, and mechanical impact. Additionally, high-quality condenser materials mitigate electromagnetic interference (EMI) and maintain consistent performance throughout the system's operational lifespan.

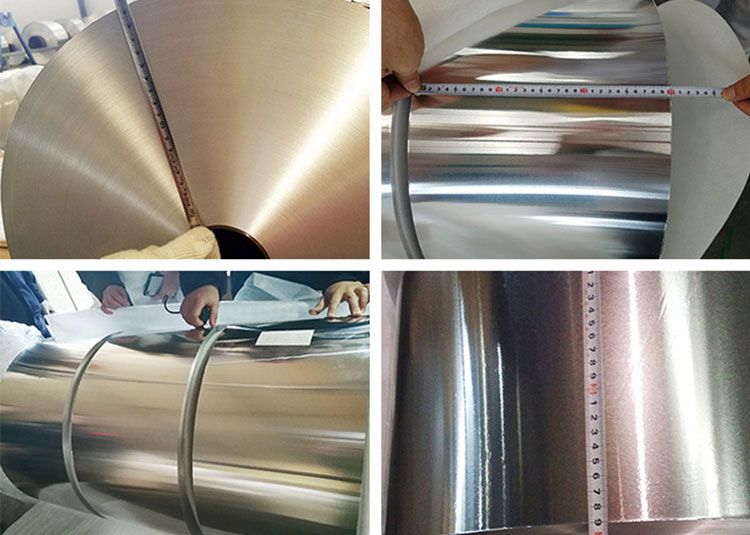

1235/8011 Aluminum Foil: Insights and Properties

When looking at 1235 and 8011 alloys combined in foils, it's important to note their intended characteristics.

ALL DIVERSION SORT

- 1235 Aluminum Foil (Alloy 1235): Offers high electrical conductivity (≥ 62% IACS), low and moderate mechanical strength, and superb formability. The winning attribute is its phenomenal corrosion resistance, allowing integration within any outdoor or challenging caustic environments without significant wear over time.

8011 Aluminum Foil: Has a slightly higher tensile strength than 1235 and is known for its exceptional barrier qualities when not only against moisture and dirt but also against electrical disturbances associated with heavy duty long-term applications, common in power grids. The flexibility and malleability of the alloy promote easy handling during installation and the complexity of environmental adaptation.

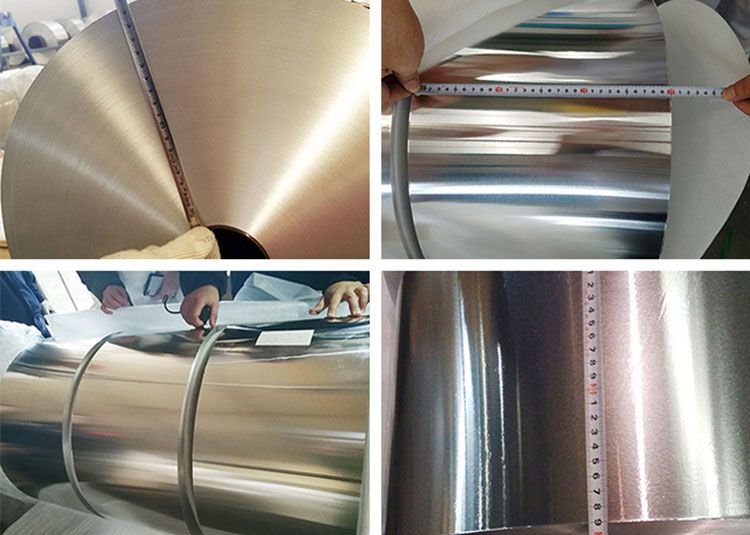

Technical Specifications Table

Below is a depiction of essential parameters and features offered by 1235/8011 aluminum foil:

| Property | Specification |

|---|---|

| Alloy Type | 1235/8011 Aluminum |

| Thickness Range | 0.006 – 0.2 mm |

| Widths Available | Up to 1,600 mm |

| Temperatures Tolerated | -20 to +80 degrees Celsius |

| Mechanical Properties | H18, O, H22 Tempers of Interest |

| Conductivity | 61% – 62% IACS (1235); more than 50% IACS (8011) |

| Chemical Composition | Al (≥99.35%) with controlled Iron and Si levels |

| Electromagnetic Shielding | Effectively minimizes operating frequency interference |

| Global Standards Complied | ASTM B479, ISO 3744, IEC 60228 |

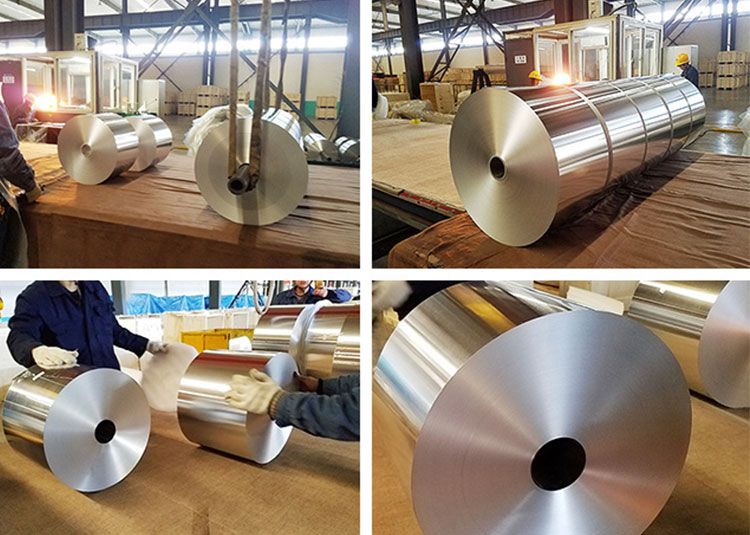

Implementing 1235/8011 in Cable Manufacturing

Utilization of 1235/8011 aluminum foil for wrapping power grid cables follows several technical considerations tantamount to quality assurance and stringent adherence to international standards.

Tension Control: Effective wrapping requires appropriate tension during application to ensure thorough compression alongside durability amongst stressors to the foil material.

Overlap Specifications: A consistent overlap area fortifies the protective function while ensuring seamless performance throughout physical adjustments under dynamic electrical attempts.

Thermal Mechanization: Heavy duty shielding in power grids requires materials that efficiently distribute temperature due to continuous high-energy output. Withstanding various gradient applications, aluminum foil continues to cement its position as a conductor throughout.

Practical Applications

Following compatibility trails resourcefully viewed from various cable constructions, 1235/8011 aluminum foils sync well with other conductive materials in installation contexts. Their high flexibility makes them utilitarian across static locations like wind farm substations, transmission grids, and both indoor-outdoor settings.

Apart from nesting formats in leading styling and tailoring, the layered shielding approach found within the power cable artery structures brings increased durability and security throughout vibrant electrical exchanges—uniform layering ensures fractional distribution, minimizing fragmentation upon high-tension movements or short circuits.