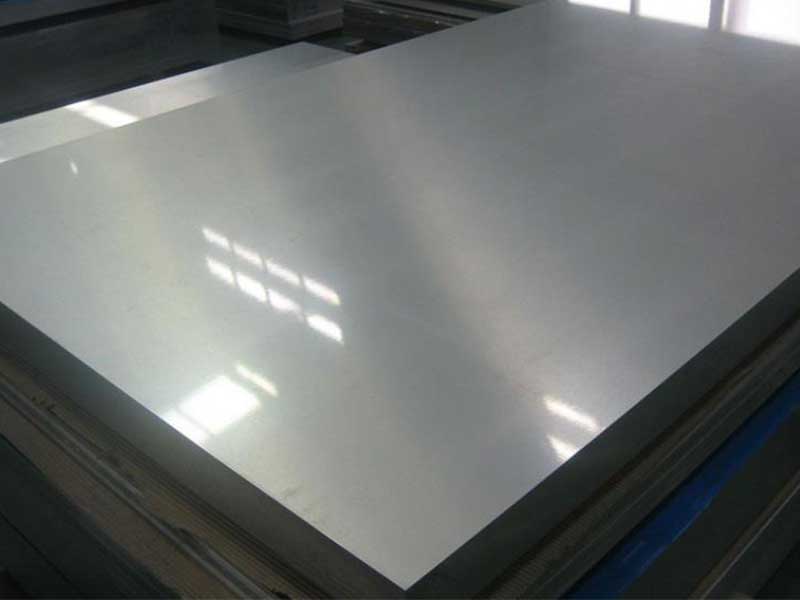

When aluminum materials, the 1000 series aluminum plate quietly asserts its significance in numerous industrial and commercial applications. Unlike other aluminum alloys designed for specialized uses, the 1000 series shines because of its outstanding purity and exceptional basic attributes, making it a go-to solution for diverse engineering and manufacturing needs.

What is the 1000 Series Aluminum Plate?

The 1000 series aluminum plate is notable for being made of 99% or higher pure aluminum. This straightforward concept of purity is one of its strongest features. For instance, the most common alloy in this series is 1050 aluminum, which typically contains 99.5% aluminum. The absence or extremely low presence of other alloying elements separates it from other aluminum series.

Working with 1000 series aluminum plate, specifically 1050 and 1070, reveals its inherent trade-offs. Its exceptionally high purity (99% or more aluminum) makes it incredibly ductile and easy to form, a boon for processes like deep drawing and spinning where complex shapes are required. This softness, however, is also its weakness. It's prone to scratching and denting, demanding careful handling throughout the manufacturing process and requiring protective measures during shipping and storage. We've seen instances where seemingly minor impacts during transport resulted in significant surface damage, leading to downgrading or rejection of otherwise perfectly good plates. Furthermore, its low strength compared to other alloys limits its applicability to structural components, confining its use primarily to applications valuing corrosion resistance and formability over high tensile strength.

Consequently, our processes are meticulously designed to account for this material’s limitations. We employ specialized tooling to minimize the risk of surface damage during fabrication. Implementing stringent quality control measures at each stage, from incoming inspection to final packaging, is crucial. We've invested in protective packaging and improved handling procedures to minimize in-transit damage. customer applications helps us advise on appropriate surface treatments, like anodizing, to enhance durability and scratch resistance where necessary. Ultimately, effectively managing 1000 series aluminum plate demands a holistic approach that balances its remarkable formability with its inherent sensitivity to mechanical stress and surface damage.

From a materials science viewpoint, 1000 series plates focus on delivering purity advantages:

- Superior corrosion resistance, especially against atmospheric and chemical environments

- Excellent electrical and thermal conductivity

- Fair formability and weldability

- Low strength compared to an alloy but compensated by other fundamental qualities

Parameters and Specifications

Here is an examination of important parameters hardware engineers and product developers consider:

| Parameter | 1000 Series Aluminum Plate (typical example: 1050) |

|---|---|

| Aluminum Content | >= 99.0% |

| Density | 2.70 g/cm³ |

| Tensile Strength (MPa) | 70 – 145 (depending on temper) |

| Yield Strength (MPa) | 42 – 110 |

| Elongation (%) | 8 – 40 (very good formability) |

| Electrical Conductivity | ~ 58 – 63% IACS (International Annealed Copper Standard) |

| Thermal Conductivity | ~ 229 W/mK |

| Melting Point | ~ 660 °C |

Note: These values vary based on specific alloys and processing conditions.

Implementation and Production Standards

International standards streamline the consistency and quality of 1000 series aluminum plates. Commonly referenced standards include:

- ASTM B209: Specification for Aluminum and Aluminum-Alloy Sheet and Plate. It details allowable element percentages, mechanical properties, and physical inspection criteria.

- EN 515: European Standard relating to aluminum and aluminum alloy sheets designed for welding, giving guidelines for workmanship and temper designations.

- JIS H4000: Japanese Aluminum Plate standards.

Compliance with such standards means an assured quality such as clear chemical composition, defined dimensional tolerances, and controlled temper states.

Alloy Tempering: Defining Material Properties through Heat and Work

Unlike many other aluminum alloy series enhanced through alloying, series 1000 mainly modifies characteristics through mechanical and thermal processing — termed 'tempers' — that control hardness, strength, and ductility.

Important delimiters for 1000 series:

| Temper Designation | Description | Effect on Mechanical Properties |

|---|---|---|

| O | Annealed (softest temper) | Maximum ductility, lowest strength |

| H12 | Quarter Hard (work hardened and quarter strength) | Enhanced strength with lower ductility |

| H14 | Half Hard (work hardened about halfway) | Balanced ductility and strength |

| H16 / H18 | Three Quarter Hard / Full hard | Highest strength, least ductility |

By applying rolling or other cold working techniques, 1000 series aluminum plates achieve different configs fitting precise application needs—the versatility of this curing method proving handy in both structural easing and electrical thermal components where workability is key.

Chemical Composition Table (for common 1050 alloy)

Each 1000 series material sticks to very minimal alloy mixture:

| Element | Max Percentage (%) |

|---|---|

| Aluminum (Al) | 99.5 (min) |

| Silicon (Si) | 0.25 |

| Iron (Fe) | 0.40 |

| Copper (Cu) | 0.05 |

| Manganese (Mn) | 0.03 |

| Magnesium (Mg) | 0.03 |

| Chromium (Cr) | 0.03 |

| Zinc (Zn) | 0.05 |

| Titanium (Ti) | 0.03 |

| Other Elements | 0.15 (each), 0.15 (total) |

This minimal alloying grants that hallmark characteristic: near-pure aluminum.

Applications: Where Purity Means Performance Advantage

The niche for 1000 series aluminum plate emerges prominently where uncomplicated composition correlates with excellent baseline properties. Its pure aluminum core reflects well in:

- Electrical industries: Cable and conductor sheet requiring high electrical and thermal conductivity

- Food and chemical industries: Because aluminum’s corrosion resistance prolongs service life in settings exposed to different atmospheres

- Reflectors and heat exchangers: Using thermal conductivity properties to maximize heat dissipation

- Architectural applications: Lightweight, though non-structural, decorative panels or veneer material

- Packaging: For foil or sheet stock where malleability is prized

A Distinctive Marketing Takeaway

If paired against alloyed aluminum counterparts, the 1000 series proponents emphasize simplicity equates reliability. This pure platform arranges customize-and-adapt philosophy by enabling downstream processing for shape, electric conduction, and surface treatment without compromising composition integrity or uncontrollable chemical reactions.

When specifying materials, professionals will consciously distinguish settings requiring consistent corrosion-proof purity or sensitive electronic efficiency precisely using 1000 series aluminum, validated and verified per modern standards.

Final Thoughts

Through total purity and malleability coupled with strict adherence to industrial standard tempers, the 1000 series aluminum plate sits as prime choice across industries prioritizing straightforward excellency. From fundamental mechanical to specialized conductivity roles, its lightweight and corrosion resistance underscore customizable impact for long-term durable outcomes.

When engineers emphasize durable simplicity exposed to air, chemicals, and heat, a small slice of 1000 series pure aluminum next to stronger alloys proves pure genius in function.

Feel free to reach out for customized alloys, delivery options, and tempered products tailored to your unique production setup—1000 series aluminum plate holds versatile keys!