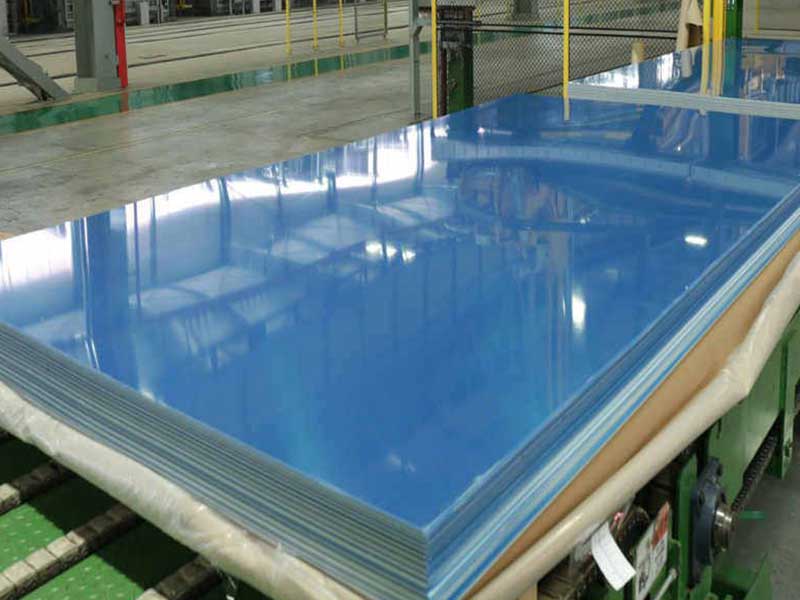

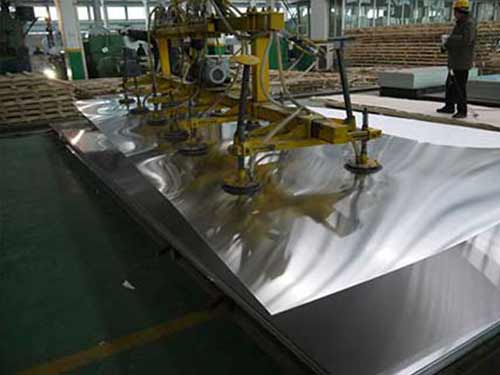

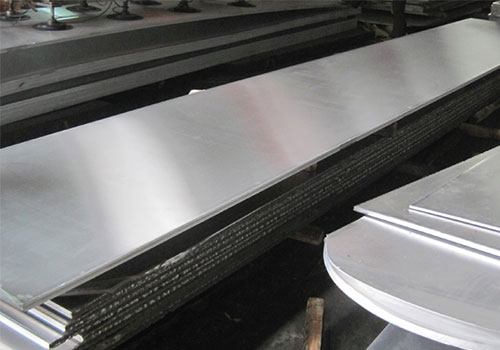

Aluminum sheet/plate in the 1xxx series (1050, 1060, 1070, 1100, 1145) is widely used wherever high electrical/thermal conductivity, excellent corrosion resistance, and good formability are more important than very high strength.

1xxx series alloys are commercially pure aluminum (typically ≥99.0% Al). They are non-heat-treatable and are strengthened mainly by cold working (H tempers, such as H14, H18).

Features (All 1050 / 1060 / 1070 / 1100 / 1145)

- High aluminum content: 99.0–99.7% Al

- Excellent corrosion resistance in most environments

- Very good electrical and thermal conductivity

- Outstanding formability and deep draw capability

- Non-magnetic, non-sparking

- Easy to shear, punch, bend, spin, and roll

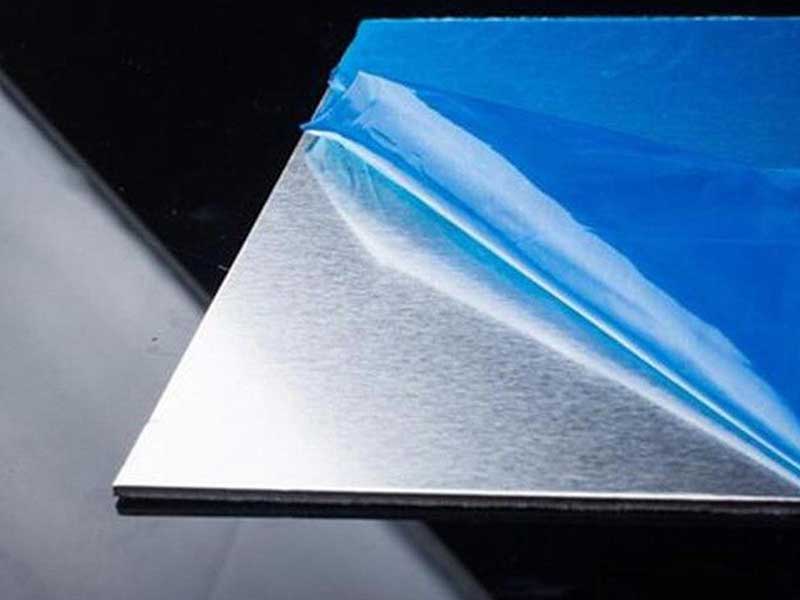

- Good surface quality for anodizing, painting, and laminating

- Food-contact safe when produced to relevant standards

2. Chemical Composition

The main difference between these grades is the minimum aluminum content and tight control of trace elements (Fe, Si, Cu, etc.).

2.1 Nominal Chemical Composition (wt.%, typical limits)

| Alloy | Al (min) | Si (max) | Fe (max) | Cu (max) | Mn (max) | Mg (max) | Zn (max) | Ti (max) | Others (each) | Others (total) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1050 | 99.50 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.10 |

| 1060 | 99.60 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | 0.10 |

| 1070 | 99.70 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | 0.04 | 0.03 | 0.03 | 0.10 |

| 1100 | 99.00 | 0.95 (Si+Fe) | 0.95 (Si+Fe) | 0.20–0.40 | 0.05 | 0.05 | 0.10 | 0.05 | 0.05 | 0.15 |

| 1145 | 99.45 | 0.55 (Si+Fe) | 0.55 (Si+Fe) | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.10 |

Note: Exact composition ranges may vary slightly by standard (EN, ASTM, GB/T). Values above are representative.

3. Mechanical & Physical Properties

These alloys are non-heat-treatable. Mechanical properties depend strongly on temper (O, H12, H14, H16, H18, etc.).

3.1 Typical Mechanical Properties (Room Temperature)

Representative values for sheet 0.5–3.0 mm (typical, not minimum guaranteed):

| Alloy | Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) | Hardness (HB) |

|---|---|---|---|---|---|

| 1050 | O | 55–95 | 20–30 | 25–40 | 20–30 |

| 1050 | H14 | 100–130 | 60–90 | 10–20 | 30–40 |

| 1060 | H18 | 130–150 | 110–130 | 4–10 | 40–50 |

| 1070 | O | 50–90 | 20–30 | 25–40 | 18–28 |

| 1100 | H14 | 110–145 | 95–120 | 8–18 | 35–45 |

| 1145 | H18 | 125–150 | 105–130 | 4–10 | 40–50 |

3.2 Physical Properties (Typical)

| Property | 1050/1060/1070/1100/1145 (typical) |

|---|---|

| Density | ~2.70 g/cm³ |

| Melting Range | 645–660 °C |

| Electrical Conductivity | 55–62 % IACS |

| Thermal Conductivity | 220–235 W/m·K |

| Coefficient of Thermal Expansion | 23–24 ×10⁻⁶ /K |

| Modulus of Elasticity | ~69 GPa |

| Poisson’s Ratio | ~0.33 |

4. Performance Characteristics

4.1 Formability & Workability

- Excellent cold formability: suitable for deep drawing, spinning, bending, roll forming.

- Soft temper (O) for complex shapes and severe forming.

- Half-hard to hard tempers (H14–H18) for better dimensional stability and strength.

Use when: you need complex geometries, light-gauge forming, or high-speed stamping.

4.2 Corrosion Resistance

- Natural oxide film provides very good corrosion resistance in:

- Atmospheric environments

- Fresh water and many mild chemicals

- 1100, with a small copper addition, offers slightly higher strength while maintaining good corrosion behavior in most environments.

For aggressive media (strong acids/alkalis, marine immersion), consider proper coating/anodizing or alternative alloys.

4.3 Electrical & Thermal Conductivity

- 1060, 1070, 1145 have very high conductivity, close to EC-grade aluminum, ideal for:

- Busbars

- Transformer windings

- Cable screens and foil

- Heat exchangers and radiator fins

4.4 Surface & Aesthetic Quality

- Smooth, clean surface for:

- Decorative anodizing (matt or bright, depending on surface finish)

- Painting, powder coating, printing, and laminating

- Food-packaging and pharmaceutical foil cladding (when rolled to foil gauges)

5. Technical Specifications & Available Forms

5.1 Thickness, Width, and Length Ranges

Typical production ranges (can be customized):

| Product Form | Thickness Range | Width Range | Length Range |

|---|---|---|---|

| Cold-rolled sheet | 0.20 – 6.0 mm | 500 – 2000 mm | 1000 – 6000 mm |

| Hot-rolled plate | 6.0 – 100 mm | 1000 – 2600 mm | 2000 – 12000 mm |

| Coil | 0.20 – 4.0 mm | 500 – 2000 mm | Coil ID: 508 / 610 mm |

5.2 Common Tempers

| Temper | Description | Typical Use Case |

|---|---|---|

| O | Fully annealed, soft | Deep drawing, spinning, complex forming |

| H12 | 1/4 hard (strain-hardened) | General forming + moderate strength |

| H14 | 1/2 hard | Structural panels, general sheet metal |

| H16 | 3/4 hard | Stiff panels, trays, cladding |

| H18 | Full hard | Foil stock, electrical, conductor use |

5.3 Standards & Certifications

Typical standards covered (depending on region and specification):

| Standard Family | Typical Designation Examples |

|---|---|

| ASTM / AA (USA) | 1050, 1060, 1070, 1100, 1145 sheet/plate |

| EN (Europe) | EN AW-1050A, EN AW-1060A, EN AW-1070A, EN AW-1100 |

| GB/T (China) | 1050, 1060, 1070, 1100, 1145 |

| JIS (Japan) | A1050, A1060, A1070, A1100 |

Material test certificates (MTC) per EN 10204 3.1 or equivalent can be supplied.

6. Comparison of the Five Alloys

6.1 Performance Snapshot

| Alloy | Al Purity | Relative Strength | Conductivity | Typical Focus Application |

|---|---|---|---|---|

| 1050 | Very high | Low | Very high | General-purpose, deep drawing |

| 1060 | Higher | Low–medium | Very high | Electrical, capacitors, conductive parts |

| 1070 | Ultra high | Low | Extremely high | Power engineering, conductor foil |

| 1100 | High | Slightly higher | High | General fabrication, tanks, vessels |

| 1145 | Very high | Low–medium | Very high | Foil stock, cable shielding, laminates |

6.2 Selection Guidelines

- For best formability with good conductivity: 1050-O or 1100-O

- For higher conductivity / electrical use: 1060, 1070, or 1145 in H18

- For general-purpose sheet metal with added strength: 1100-H14

- For foil and thin gauge cladding: 1145, 1070 in hard tempers

7. Typical Applications

7.1 Electrical & Thermal

- Busbars and bus ducts

- Transformer and reactor windings

- Cable shielding, cable wraps, and foil

- Heat sinks, radiators, and heat exchanger fins

- LED substrates and thermal management pads

7.2 Packaging & Consumer Goods

- Food and pharmaceutical packaging foil (from 1145, 1070)

- Bottle caps and closures

- Cookware, kitchen utensils, and household goods

- Cosmetic and aerosol can bodies (deep drawing grades)

7.3 Building & Industrial

- Roofing, wall cladding, and decorative façade panels

- Insulation jacketing for pipelines and equipment

- Nameplates, signage, and advertising panels

- Chemical and food storage tanks (1100 often preferred)

- Ventilation ducts, cable trays, and light structural elements

7.4 Transportation & Other Uses

- Interior trim in vehicles, buses, and rail

- HVAC housings, brackets, and covers

- Reflector panels (polished or anodized 1050/1060)

- Laminated composites with plastic, paper, or other metals

8. Benefits for Customers

8.1 Cost-Effective Performance

- Lower alloy content means cost advantage over many 5xxx/6xxx alloys.

- Excellent trade-off between conductivity, formability, and price.

8.2 Manufacturing Efficiency

- Predictable behavior in stamping, spinning, and forming, reducing scrap rates.

- Suitable for high-speed coil processing: cutting, slitting, blanking.

8.3 Long-Term Reliability

- Stable properties over time; no risk of over-aging (non-heat-treatable).

- Good corrosion resistance reduces maintenance and replacement frequency in many environments.

Aluminum sheet and plate in grades 1050, 1060, 1070, 1100, and 1145 provide a versatile family of high-purity, high-conductivity, corrosion-resistant materials. They are ideal when you require:

- Excellent formability and surface quality

- High electrical/thermal conductivity

- Reliable performance at a competitive cost

By selecting the appropriate alloy and temper, you can optimize your product for electrical performance, forming behavior, or general fabrication, ensuring a balanced solution for both technical performance and total lifecycle cost.