In the packaging and food industries, aluminum foil remains an indispensable material for preserving freshness, providing barrier protection, and ensuring product safety. Two commonly used aluminum foil alloys for food contact applications are 8011 and 8079.

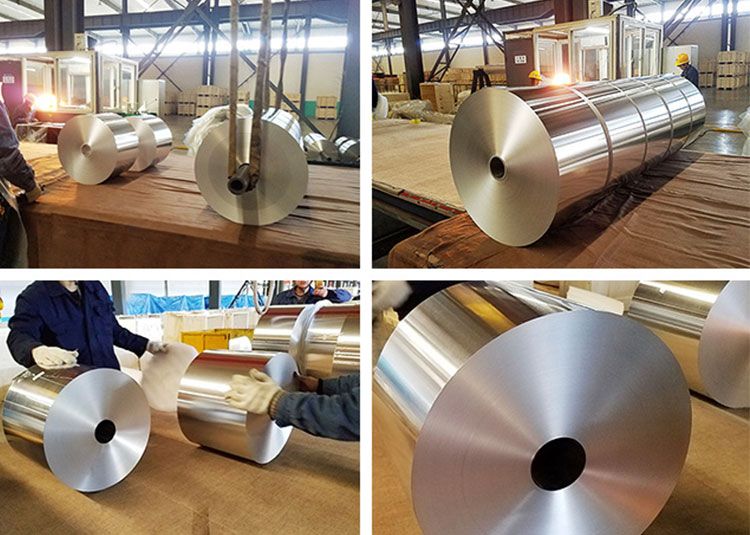

The 8011 and 8079 alloys are widely acknowledged in the production of high-quality food aluminum foil rolls. Both alloys exhibit excellent formability, corrosion resistance, and barrier properties. The jumbo roll format allows manufacturers and converters to execute efficient slitting, cutting, and laminating processes, ensuring streamlined production flows in packed food packaging.

Features of 8011 8079 Alloy Aluminum Foil Jumbo Roll

| Feature | Description |

|---|---|

| Excellent Formability | Superior ductility enables multi-layer rolling with excellent surface finish |

| Food-Grade Safety | Compliant with food contact regulations; non-toxic and odorless |

| Good Barrier Properties | Provides protection against moisture, oxygen, UV rays, and external contaminants |

| Corrosion Resistance | Enhanced chromium content improves corrosion resistance |

| Dimensional Stability | Precision-engineered thickness and width ensure uniformity and minimize process wastage |

| High Surface Finish Quality | Smooth, clean surface perfect for lamination and printing applications |

| Jumbo Roll Availability | Supplied as jumbo rolls ranging from 400mm to over 1800mm in width, beneficial for large operations |

Chemical Composition

The defining difference between the 8011 and 8079 alloys largely involves minor variations in trace elements aimed at improving usability while ensuring corrosion resistance and mechanical performance.

| Element | 8011 Alloy (wt%) | 8079 Alloy (wt%) |

|---|---|---|

| Aluminum (Al) | Balance (Minimum 96.7%) | Balance (Minimum 99.0%) |

| Iron (Fe) | 0.40 - 0.80 | 0.40 - 0.90 |

| Silicon (Si) | 0.11 - 0.50 | 0.05 - 0.45 |

| Manganese (Mn) | 0.03 - 0.20 | ≤ 0.10 |

| Copper (Cu) | ≤ 0.05 | ≤ 0.04 |

| Chromium (Cr) | 0.05 - 0.20 | ≤ 0.15 |

| Zinc (Zn) | ≤0.05 | ≤ 0.12 |

| Others | ≤ 0.15 | ≤ 0.14 |

Note: Variation in chemical composition depends on manufacturer specifications but is controlled to optimize foil properties.

Technical Specifications

| Parameter | Typical Value | Unit |

|---|---|---|

| Thickness | 0.006 - 0.2 | mm |

| Width (Jumbo Roll) | 400 - 1800 | mm |

| Temper | O (Annealed to Soft), H14 (Half Hard) | |

| Density | 2.70 | g/cm³ |

| Ultimate Tensile Strength | 70 - 130 | MPa |

| Yield Strength | 40 - 85 | MPa |

| Elongation at Break | 15 - 35 | % |

| Surface Finish | Bright surface, can be dull or matte | - |

| Coating (Optional) | Food-safe lacquer, heat-sealable coatings | - |

| Oven-Safe Limit | Up to 220 | °C (For cooked food wrapping) |

Applications

Food Packaging Industry

- Flexible Food Wrapping: Ultra-thin foil across 8011 and 8079 alloys effectively seals freshness for snacks, confectionaries, frozen foods, and bakery products.

- Laminated Structures: Jumbo rolls used to produce laminated foil papers for food pouches, ensuring high barrier protection while maintaining flexibility.

- Cooking Foils: Oven and microwave-safe foils suitable for direct food cooking, reheating, or grilling.

- Disposable Food Containers: Range of foil thickness meets rigidity requirements for disposing food containers and trays.

Pharmaceutical & Cosmetic Packaging

- Safety packaging that ensures moisture, contamination-proof sealing for high-value, sensitive products.

Industrial Uses

- Insulation layers in manufacturing.

- Barrier materials in product handling and storage.