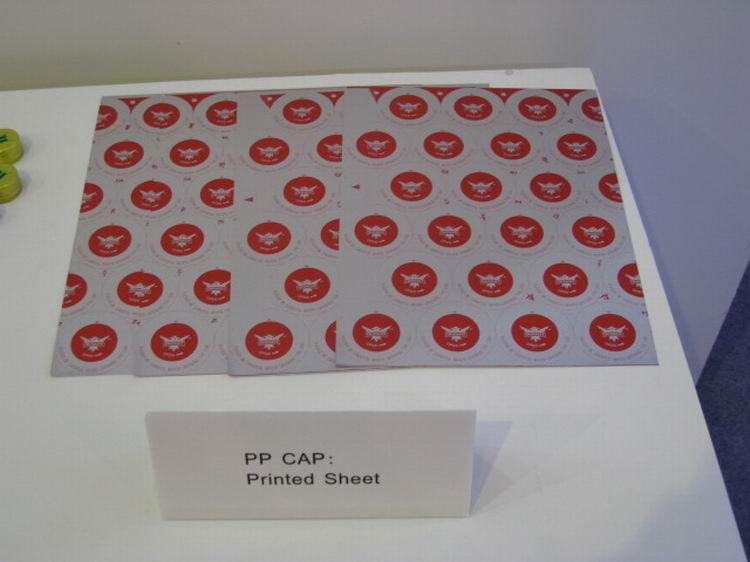

In the realm of packaging, especially in the production of polypropylene (PP) caps, material selection is paramount to achieving both functional performance and cost efficiency. Among the top-tier choices, 8011 aluminum sheet stands out as an industry favorite for aluminum closure sheets due to its superior properties tailored for PP cap applications. Today, we explore 8011 aluminum sheets from a unique technical vantage point to reveal why it's the ideal grade for PP cap material.

What Makes 8011 Aluminum Sheet Ideal for PP Cap Materials?

Aluminum sheets for PP caps require a particular balance of strength, corrosion resistance, and ease of forming to integrate seamlessly with the plastic substrate and deliver airtightness and durability. The 8011 alloy uniquely balances these criteria:

- High Corrosion Resistance: Crucial due to the frequent contact with liquids and the wide temperature ranges during capping and storage.

- Excellent Flexibility and Formability: To conform efficiently to intricate cap designs without structural failure.

- Surface Compatibility: Smooth laminar surface suited for coating and bonding processes with polypropylene.

Technical Specifications & Implementation Standards for 8011 Aluminum Sheets

the mechanical and chemical foundations of 8011 alloy aids manufacturers in ensuring compliance and quality consistency. The following parameters provide a clear framework for evaluating raw materials:

| Parameter | Details |

|---|---|

| Alloy Designation | 8011 |

| Temper | H14, H18 (common tempers for caps) |

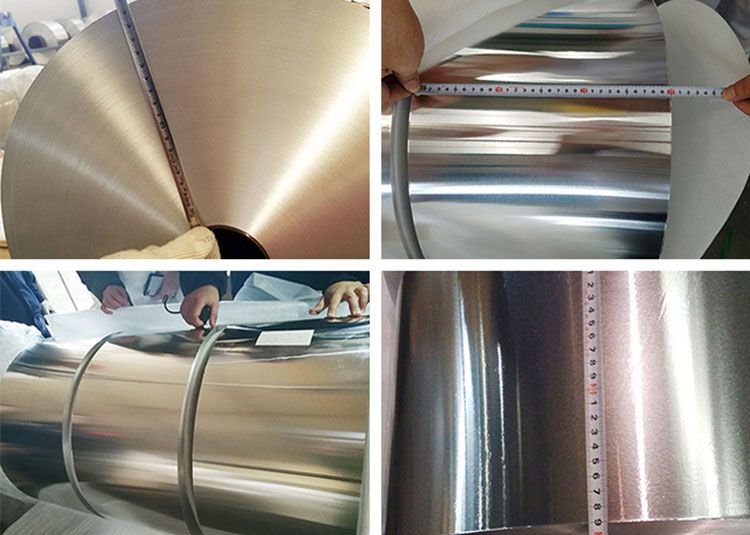

| Thickness Range | 0.030 mm – 0.15 mm |

| Width Range | Up to 1200 mm |

| Yield Strength (H14) | Min. 75 MPa |

| Tensile Strength (H14) | 110 – 140 MPa |

| Elongation | 2 - 6 % |

| Density | 2.71 g/cm³ |

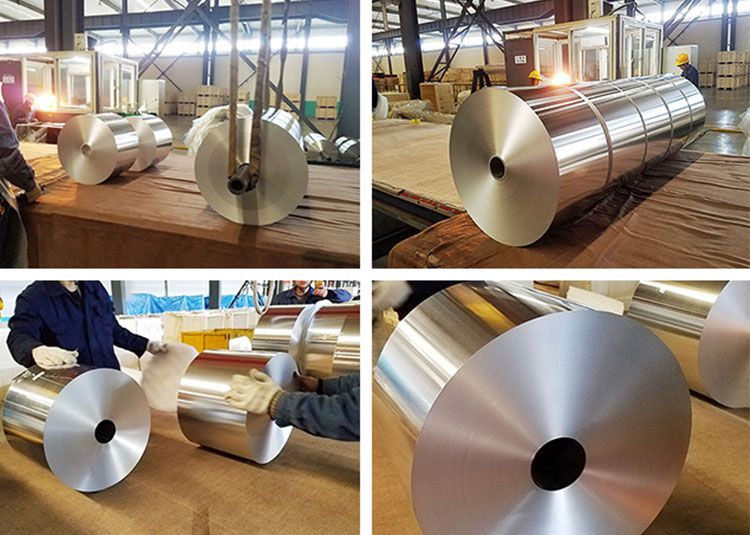

| Coil or Sheet Form | Available as roll stock or flat sheet |

Implementation Standards:Manufacturing and quality control typically adhere to the ASTM B209 standard - Specification for Aluminum and Aluminum-Alloy Sheet and Plate and EN AW-8011 designations. These regulations ensure consistent mechanical integrity for processing and end-use durability, particularly necessary in the food and cosmetics packaging sectors.

Chemical Composition: Enhanced Balance for Closure Sheet Applications

A distinguishing hallmark for 8011 used in PP caps is its optimized alloy content, specifically prepared to maintain delicacy for thin closure sheets, yet impart resilience:

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | Balance (99.0% min) |

| Iron (Fe) | 0.20 - 0.70 |

| Copper (Cu) | 0.05 - 0.20 |

| Manganese (Mn) | 0.30 - 0.85 |

| Silicon (Si) | 0.30 - 0.60 |

| Zinc (Zn) | 0.10 max |

| Others (Each) | 0.05 max |

This formula creates an alloy distinguished by corrosion resistance against minty liquids and enhances adhesion compatibility with PP resin during lamination or bonding, preventing delamination and enhancing longevity.

Altering Tempering for Precision Applications in PP Cap Production

- H14 Temper: Often used when moderate hardness and ability to undergo moderate forming without cracking is needed. Perfect for storage caps and general-purpose closures.

- H18 Temper: Stiffer yet ductile enough for deep forming caps, essential for caps exposed to higher pressures or stress conditions.

Temper selection inherently affects how the 8011 sheet behaves during cap pressing and shaping – delicate balance where strength must co-exist with malleability.

Additional Superior Traits Favoring 8011 in PP Cap Material Use

- Thermal Stability: Minimal expansion under temperature, ideal where lids undergo sterilization or hot-filling.

- Eco-Friendly and Fully Recyclable: Aluminum can be infinitely recycled without quality loss, aligning with growing environmental concerns in packaging.