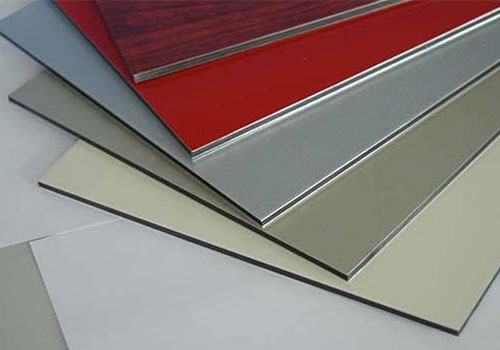

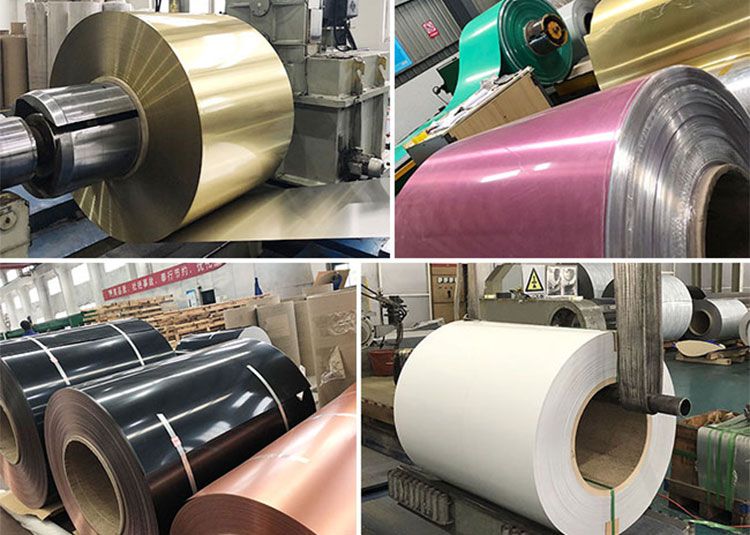

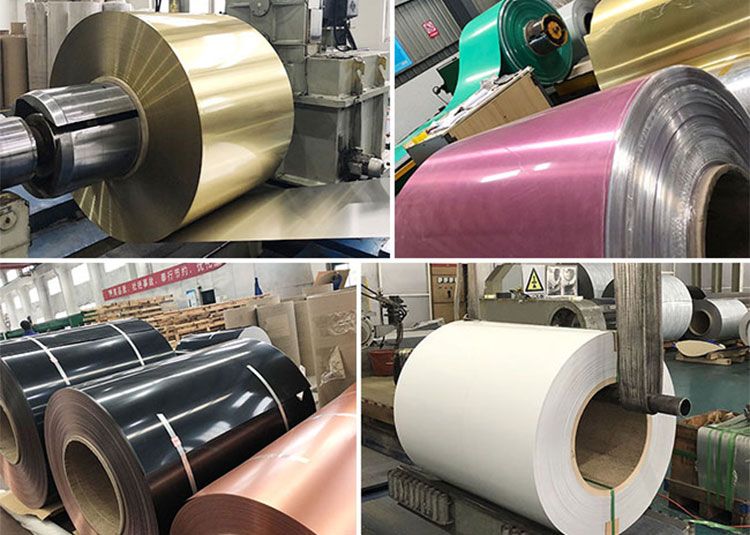

In the evolving landscape of construction and design materials, 0.8mm color coated aluminum coils are setting a new standard for durability and aesthetic versatility. From residential siding to modern facades, this product has gained professional acclaim because of its peculiar combination of properties.

0.8mm Color Coated Aluminum Coil

Typically fashioned to be both lightweight and resilient, a 0.8mm color coated aluminum coil serves as a flexible tank to capture industrial and creative user trends in material applications. Its thickness—0.8mm—strikes a careful balance between structural strength and the ability to be bent into various shapes, ideal for a plethora of creative solutions.

Parameters

Here are important specifications for 0.8mm color coated aluminum coil, which makes it a competent option for diverse applications:

| Parameter | Specification |

|---|---|

| Thickenss | 0.8 mm |

| Alloy Types | 1100, 1060, 3003 |

| Coating Thickness | 20 to 150 microns |

| Yield Strength | 150 - 200 MPa |

| Elongation | > 5% |

These parameters empower fabricators and contractors to optimize material selection for their specific applications without compromising performance reliability.

Implementing the Standards

implementation standards associated with 0.8mm coated aluminum is crucial for both purveyors and consumers. This product adheres to the internationally recognized ASTM B209 and GB/T 3880 standards. These guidelines ascertain properties including thickness, flatness, and fallibility which comply with aesthetic, structural, and technical requirements. Furthermore, compliance with ISO 9001 certification demonstrates the manufacturer's capability in maintaining consistent quality that transcends diverse applications.

Alloy Tempering Acceptance

The alloy composition blends play a significant role when considering 0.8mm color coated aluminum. Typically composed of alloying elements such as Magnesium (Mg) and Manganese (Mn), these alloys enhance mechanical properties and performance characteristics:

- Alloy 1100: Offers exceptional corrosion resistance while providing ease of workability and formability.

- Alloy 3003: Features robust mechanical strength paired with good weldability, ideally suited for light-weight applications prevalent in ventilation ducts.

- Temper status Twilight: Primarily designed as annealed or H14, ensuring excellent strength-to-weight ratios and bendability.

This specific combination of alloys and tempers ensures that whether the context is in roofing, siding, or interior applications, achieving nuanced performance characteristics become commonplace in day-to-day bonding use including paintability and post-processing treatments.

Chemical properties dictate material function and usability, especially in environments prone to weathering or corrosive exposure. Here’s a concise table of the chemical composition:

| Element | Concentration (%) Integer |

|---|---|

| Aluminum (Al) | ≥ 98% |

| Magnesium (Mg) | 0.5 to 1.5 |

| Manganese (Mn) | 0.05 to 0.35 |

| Silicon (Si) | ≤ 0.3 |

| Iron (Fe) | ≤ 0.4 |

| Zinc (Zn) | ≤ 0.1 |

The excellence of coated aluminum hinges upon how multiple critical properties cover robustness, corrosion resistance, and decent weldability indicate the resilience dynamics positively serving any structural intentions.