In the world of metals and construction materials, the white painted aluminum sheet stands out as an intersection where function meets fine finishing. More than merely a color-coated flat panel, this product offers a unique combination of technical sophistication, protective qualities, and versatile applications that address both engineering precision and architectural aesthetics.

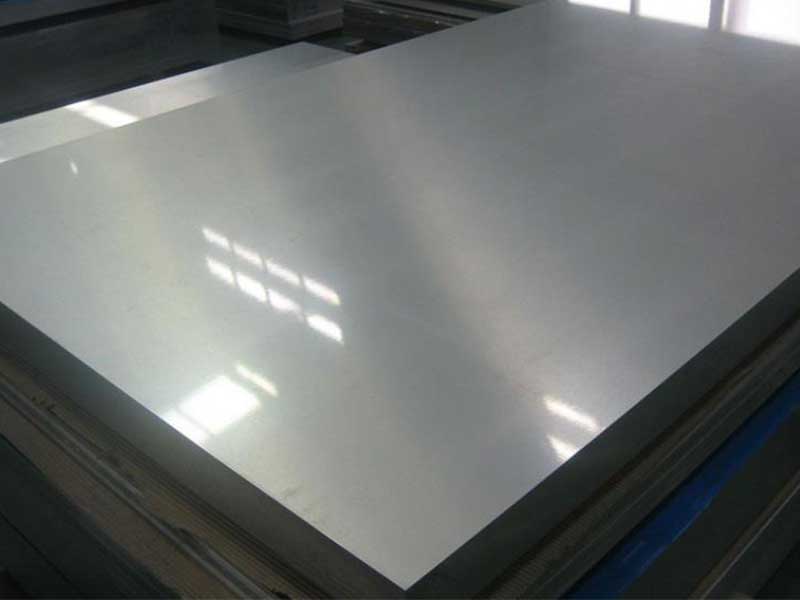

White painted aluminum sheet refers to aluminum sheets that have undergone a surface treatment of high-quality paint in white tones. Typically, these sheets start as raw aluminum—often alloyed to optimize strength and workability—then move through a controlled tempering process. The painting procedure uses advanced coating technologies such as coil coating with polyester or PVDF (Polyvinylidene fluoride) paints, designed to adhere firmly and retain durability.

Technical Parameters and Standards

| Parameter | Description | Typical Value/Range |

|---|---|---|

| Alloy Type | Common aluminum alloys used | 3003, 3105, 5005 |

| Temper | Alloy temper for hardness & formability | H14 (half hard), H18 |

| Coating Thickness | Thickness of the paint layer | 18-25 microns |

| Paint Type | Polyester standard / PVDF for high durability | PVDF preferred for outdoor use |

| Thickness Range (Sheet) | Aluminum base sheet thickness | 0.2 mm to 3.0 mm |

| Width Range | Sheet width | 1000 mm to 1650 mm |

| Mechanical Strength | Tensile Strength for different tempers | Approx. 110 MPa (H14), up to 145 MPa (H18) |

| Standards Compliance | Manufacturing and coating standards | ASTM B209 / DIN EN 485, AAMA 2605 |

Subtle Power of Aluminum Alloys and Tempering Process

The backbone of white painted aluminum sheets lies in the alloy and its tempering conditions. Alloys like 3003, 3105, and 5005 blend copper, magnesium, and manganese to bolster corrosion resistance and mechanical strength. Use of the H14 temper imparts stiffness essential for residential and industrial wall panels, while maintaining workability.

Tempering defines not just hardness but formability—a final H18 temper, for example, balances strength and bending aptitude, a crucial characteristic for fabrication.

Chemical Composition Snapshot

The optical appeal of white paint is underpinned by aluminum’s inherent chemical resilience:

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Others (%) |

|---|---|---|---|---|---|---|---|---|

| 3003 | ≤ 0.6 | ≤ 0.7 | 0.05-0.20 | 1.0-1.5 | ≤ 0.10 | ≤ 0.10 | ≤ 0.20 | Balance Al |

| 3105 | ≤ 0.6 | ≤0.8 | ≤0.05 | 0.20-0.50 | ≤ 0.10 | ≤ 0.10 | ≤ 0.20 | Balance Al |

| 5005 | ≤ 0.40 | ≤ 0.70 | ≤0.05 | ≤ 0.1 | 0.30-0.70 | ≤ 0.10 | ≤ 0.20 | Balance Al |

Inherent aluminum weather resistance plus the white paint’s UV block factor offer a robust shield against corrosion agents and UV degradation.

Functional Benefits Under a Multifaceted Lens

- Weather & Corrosion Resistance: The white paint coating, particularly with PVDF finishes, resists chalking, peeling, and fading in demanding environments, supporting longevity for solar reflectance facades.

- Thermal Properties: The white color improves light reflection and decreases thermal absorption, mitigating heat buildup and contributing to energy-efficient building envelopes.

- Lightweight but Strong: Thanks to aluminum’s strength-to-weight ratio, fabricated sheets supported with ideal alloy and temper selection make durable and lightweight panels, preserving structural integrity while reducing installation labor and transportation cost.

- Maintenance and Cleanability: Smooth painted surfaces offer high cleanability; dirt and grime do not easily adhere, simplifying upkeep especially in urban or coastal installations.

Applications Where Form Meets Function

- Architectural Panels and Exterior Facades: Leveraging high reflectivity and longevity, architects favor white painted aluminum sheets in commercial buildings, shopping centers, and airports.

- Clean Rooms and Laboratory Wall Coverings: Easily sanitized and resistant to chemicals, these sheets benefit sterile environment fabrication.

- Signage and Advertising Boards: The accurate visual contrast of white paint coupled with printability enables high-visibility advertising platforms.

- Appliances and HVAC Covers: Since aluminum dissipates heat efficiently and maintains surface quality, manufacturers use white painted sheets structurally and aesthetically in appliances and ventilation housings.

- Transportation Interiors: Buses, trams, and train carriages incorporate these panels for luggage racks and internal cladding — balancing weight savings with a bright interior ambiance.

Implementation Best Practices

Adherence to temperature and humidity-controlled painting environments guarantees uniform paint thickness and robust bonding to the alloy surface. Strict testing protocols covering adhesion (ASTM D3359), abrasion resistance, and color stability (ASTM G155 - Xenon arc weathering) ensure the sheets’ superior functional lifespan. All stages—rolled sheet preparation, primer application, painting, curing—must meet industrial standards such as AAMA 2605 for extrusion coatings.