In an era where aesthetics meet functionality, the High Reflective Mirror Finish Aluminum Coil stands out as a distinctive solution for various industrial and decorative applications. Unlike ordinary aluminum sheets, this product marries meticulous surface craftsmanship with advanced material science to achieve exceptional reflectivity and durability — a true marvel of modern metallurgy.

What Is a High Reflective Mirror Finish Aluminum Coil?

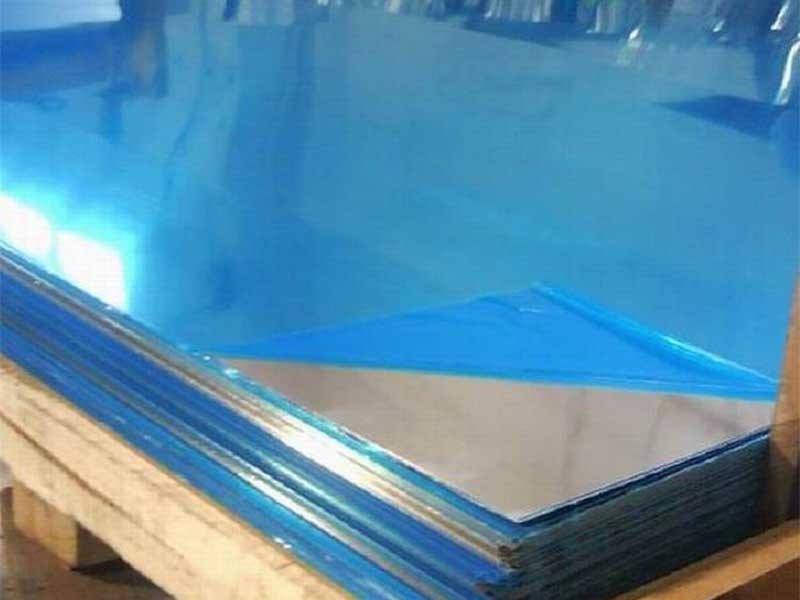

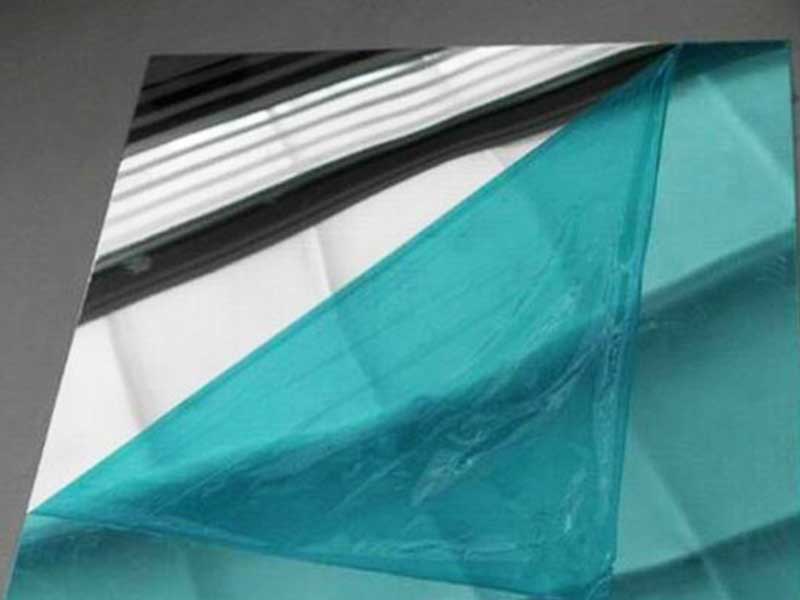

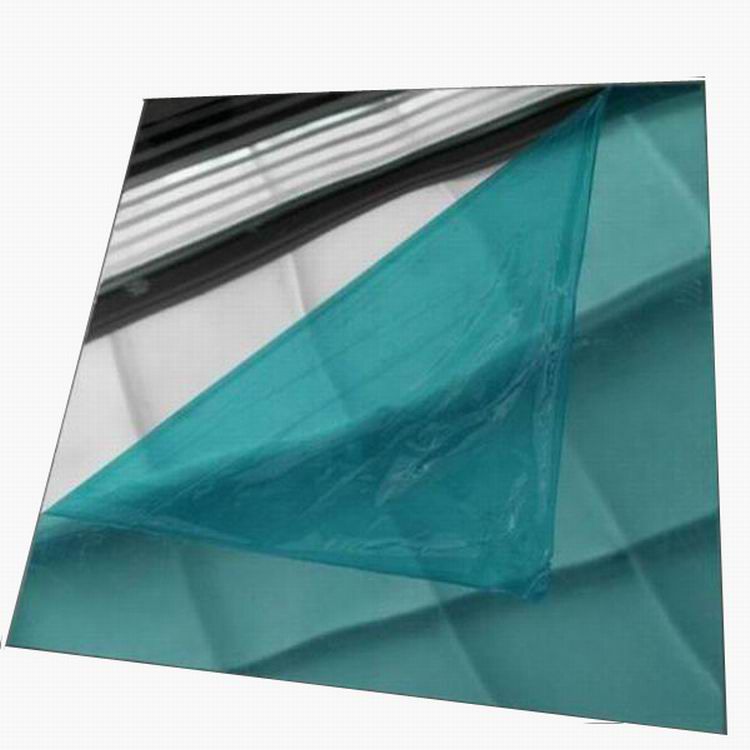

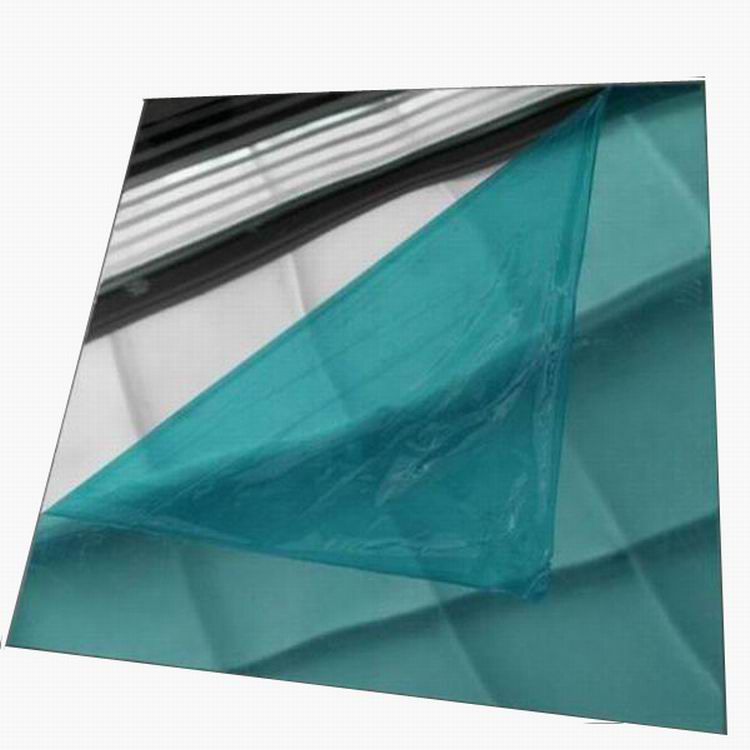

Simply put, it is an aluminum coil that has undergone precision polishing processes to deliver a mirror-like reflective surface. This finish isn't superficial gloss but a deep polish that results in reflectance levels exceeding 85%, rivaling even some specialized reflective metals like polished stainless steel. The aluminum coil format enables ease of transportation, processing, and fabrication, making it a sought-after option for architects, designers, and industrial manufacturers.

The Unique Importance of Reflectivity

Reflectance in aluminum coil isn’t just about visual appeal; it plays a crucial role in practical applications such as lighting fixtures, solar reflectors, signage, transportation, and heat exchangers. A superior natural mirror finish ensures maximum light reflection, boosting energy efficiency and reducing electrical consumption in lighting and solar energy systems. Additionally, the shiny surface helps in ambient cooling and reduces solar heat absorption, which can be pivotal in certain engineering contexts.

Alloy Series and Tempering Conditions

The foundation of this brilliance lies in the aluminum alloy composition and treatment. The most commonly used alloys for reflective mirror finish aluminum coil are from the 1xxx, 3xxx, and 5xxx series due to their purity, workability, and corrosion resistance.

| Alloy | Chemical Composition (Weight %) | Notes |

|---|---|---|

| 1100 | Al ≥ 99.0% | High purity aluminum for maximum reflectivity and corrosion resistance |

| 3003 | Al min Balance, Mn 1.0%-1.5%, Cu 0.05%-0.20% | Added manganese improves strength with good formability |

| 5052 | Al min Balance, Mg 2.2%-2.8%, Cr 0.15%-0.35% | Noteworthy corrosion resistance suitable for marine environments |

Temper Designations:

- H14: Half-hard temper suitable for moderate skin hardening without compromising ductility, ideal for mirror finish surfaces.

- H18: Full hard temper offering a balance of strength and ambient stability, often preferred in structural reflective surfaces.

- HR (Hot Rolled) or CR (Cold Rolled) coils are then mechanically polished for achieving fine surface smoothness.

Manufacturing and Finishing Process

Achieving this mirror finish is both a science and an art. It involves sequential grinding with progressively finer abrasives, followed by meticulous chemical and mechanical polishing processes. The process can use alumina or cerium oxide polishing compounds to minimize microscopic surface roughness, reaching reflectivity of ≈85-90%.

Strict quality control measures are integral. Surface reflection is measured in photometric labs with reflectometers, verifying consistency. Any surface deformation or contamination is unacceptable as these imperfections reduce reflective capability.

Implementation Standards

Adherence to international standards ensures material reliability and performance.

- ASTM B209 — Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate provides material property benchmarks.

- EN 573 — Defines chemical composition and formability of wrought aluminum and aluminum alloys.

- ISO 9001 — Quality management standards aligned with finishing processes.

Parameters Snapshot:

| Parameter | Typical Value |

|---|---|

| Reflectance (%) | ≥ 85 (visible spectrum, 400-700 nm) |

| Surface Roughness | Ra ≤ 0.2 microns |

| Coil Thickness | 0.3mm – 2.0mm |

| Coil Width | 1000 mm – 1550 mm |

| Tensile Strength | 90 – 150 MPa (dependent on alloy and temper) |

| Elongation (%) | 8 – 15% |

Applications Beyond Beauty

Its superior reflectivity, corrosion resistance, and malleability makes this coil fit for:

- Architectural claddings and facades: Presenting gleaming exteriors that impress visually and last longer indoors or scattered sunlight.

- Lighting industries: Reflectors in luminaires where efficiency hinges on surface conditions.

- Solar energy panels: Maximize light capture for photovoltaic efficiency.

- Transportation and automotive interior trim: Stylish yet durable appearance layers.

- Consumer electronics and appliances: Brushed aluminum is passé – mirror finish represents futuristic industrial design.