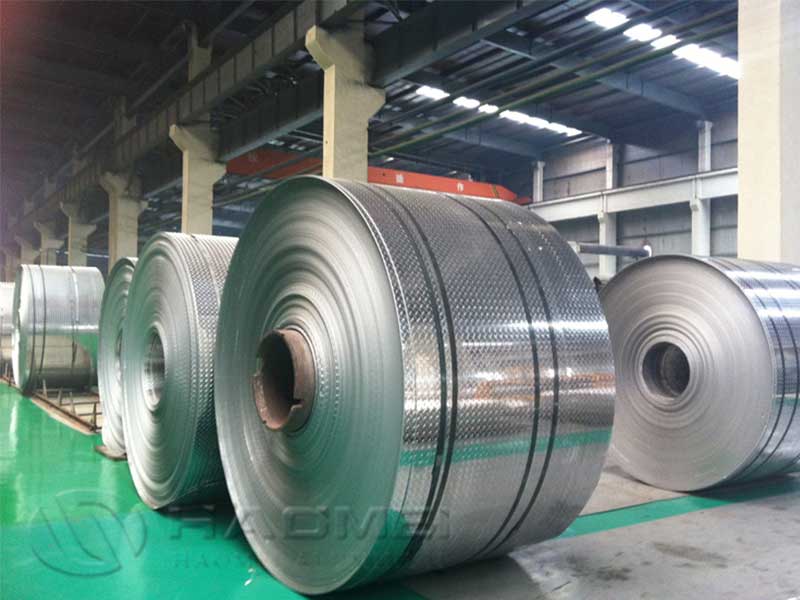

When it comes to combining durability with a sleek, practical design, the aluminium embossed sheet with 5 bars emerges as a top performer in metal fabrication and architectural applications. Beyond being just a metallic sheet, its structured pattern and alloy properties respond beautifully to the demands of multiple industries — from construction to transport and interior design.

What is an Aluminium Embossed Sheet with 5 Bars?

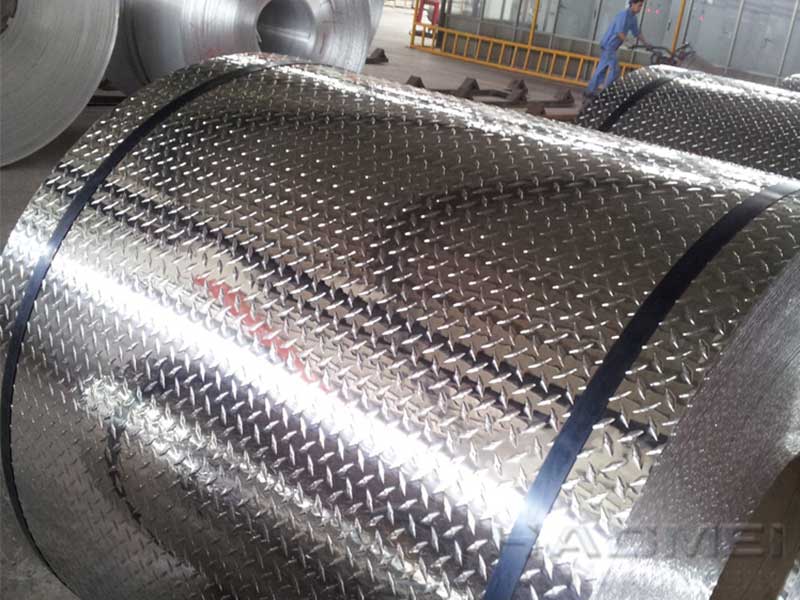

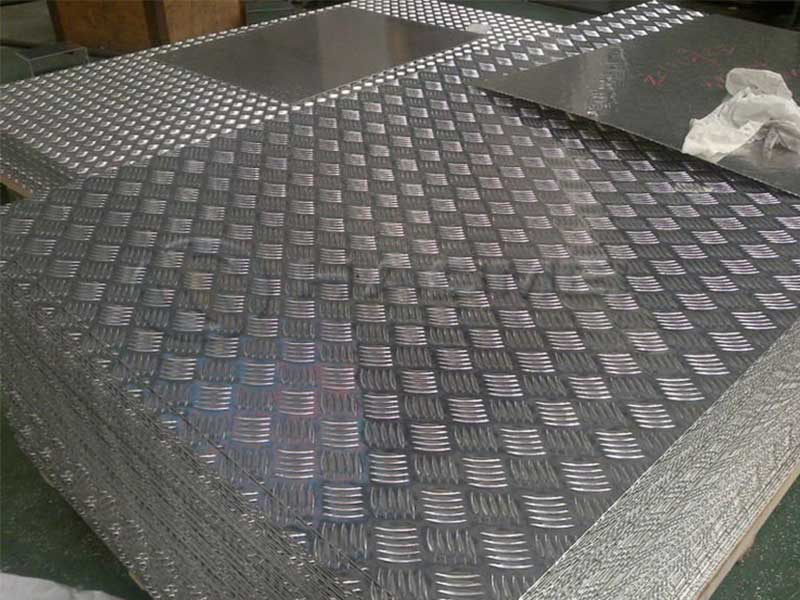

An aluminium embossed sheet features raised patterns on its surface, a process known as embossing or tread plating. The “5 bars” variant indicates that the embossed pattern consists of five parallel raised bars (or ribs) arranged consistently across the surface. These bars offer additional grip and strength compared to smooth sheets.

We run a lot of 5-bar embossed aluminum sheet through our production line here, and it's fascinating to see the subtle variations even within that seemingly simple specification. The depth of the embossing, for example, can significantly impact the final product's stiffness and its ability to withstand bending or denting. We've had instances where a slightly shallower emboss than usual led to increased complaints from customers using it in applications demanding more structural integrity. Similarly, the uniformity of the bars across the sheet is critical; inconsistent embossing can lead to uneven paint application, a common concern we address in our quality control. Even the alloy of the aluminum itself plays a role – some are more prone to scratching during handling, requiring adjustments to our internal processes.

My personal insight is that the "5-bar" designation, while seemingly straightforward, actually masks a surprising level of complexity. Each sheet is a testament to the interplay of material science, manufacturing precision, and ultimately, the end-user's needs. the nuances of the embossing process, the subtle differences in raw materials, and the specific application for which the sheet is destined are to producing a consistently high-quality product. It's a far cry from simply stamping out uniform patterns; it’s about managing a complex interplay of factors to meet a range of customer expectations.

This specific embossing ensures higher anti-slip properties which is crucial for flooring, staircases, ramps, and truck beds. Unlike standard plain sheets, the bars also help in structural rigidity, dispersing stresses more evenly and increasing load-bearing capacity.

Technical Parameters and Implementation Standards

Aluminium embossed sheets with 5 bars follow specific international and regional standards designed to guarantee quality performance.

| Parameter | Typical Specification |

|---|---|

| Thickness | 1.5 mm to 5 mm |

| Width | 1000 mm to 1500 mm |

| Length | Up to 6000 mm, customizable |

| Surface Texture Pattern | 5-bar embossed linear raised bars |

| Standard Code | ASTM B209 for aluminum and aluminum-alloy sheet/plate |

| Strength Grade | Temper ranges from O (annealed) to H14 (partial hard) |

| Typical Alloy Type | 3003-H14 (moderate strength, good corrosion resistance) |

- Thickness: Ranges based on usage requirement—thin sheets for easier bending, thicker plates for heavy-duty loads.

- Width and Length: Adaptable for ease of shipment and fabrication.

- Temper: Amid multiple tempers, H14 provides a beneficial balance between malleability and strength retaining. O temper indicates annealed sheets with maximum ductility.

Alloy Types and Tempering Explained

which alloy and heat treatment temper are used defines the practicality of the embossed sheet.

3003 Aluminum Alloy is the most frequently used in these embossed sheets because:

It contains manganese (about 1.2%) which enhances corrosion resistance.

Provides overall formability, weight reduction, and strength suitable for architectural and light industrial use.

Common Tempers:

O (Annealed): Soft and ductile, optimal for forming or bending applications.

H14 (Half-hard): Work-hardened which increases strength and hardness, widely preferred for durable tread plating.

Chemical Composition of Aluminium 3003 Alloy (% by weight)

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Aluminum | Balance | N/A |

| Copper | - | 0.10 |

| Manganese | 1.0 | 1.5 |

| Iron | - | 0.7 |

| Silicon | - | 0.6 |

| Zinc | - | 0.1 |

| Magnesium | - | 0.10 |

| Other | - | 0.15 |

manganese infusion contributes CE corrosion resistance making it durable under different environmental conditions

Why Choose Aluminium Embossed Sheets with 5 Bars?

- Enhanced Slip-Resistance: The 5-bar design provides a gripping surface essential for safety, preventing slips even in oily or wet environments.

- Elevated Strength and Durability: The embossed profile increases rigidity more than plain sheets without significantly raising weight, balancing sturdiness and transport ease.

- Lightweight Property: Aluminium is nearly one-third weight of steel but matches the corrosion resistance with proper coating and alloy selection.

- Versatile Applications: From flooring in factories, steps in vehicles, ramp covers, decorative façade panels, to protective coverings, the 5-bar layout fits multiple uses.

- Corrosion-Resistance & Low Maintenance: 3003 alloy's protective qualities cut down long-term maintenance efforts even when exposed outdoors.

Implementation and Fabrication Tips

- Cutting: Can be performed with mechanical shears, water jets, or plasma cutting depending on sheet thickness.

- Welding: Aluminum welding skills required for stronger joins; alternatively rivets or bolts can be used for assembly.

- Maintenance: Aluminum requires minimal care—occasional cleaning and checks for damages prolong life.

- Surface Finish: Available in mill finish or anodized variants adding further weather resistance.

In Conclusion

The aluminium embossed sheet with 5 bars is a balanced blend of functional design and mechanical advantage. Optimal temper treatments paired with beneficial alloy compositions make it a reliable choice in safety-conscious and structural applications. By selecting the right thickness, temper, and alloy composition, this tough yet lightweight material adapts brilliantly to modern fabrication standards and user safety needs. Whether it’s commercial flooring or vehicle fittings, its textured pattern combined with excellent corrosion-resistant properties ensures longevity and robustness.

Established guidelines and best production standards make aluminium embossed sheets not only a practical but an economically-sound investment for long-term use—solidifying their standing in metal sheet innovation and application.