Aluminum plates serve as foundational materials across numerous industries, from automotive manufacturing to shipbuilding and construction. Among these, the 5754 aluminum plate stands out as an exceptional choice due to its unique blend of strength, corrosion resistance, and formability. the technical parameters, chemical properties, and suitable applications of the 5754 aluminium alloy offers invaluable insight into why architects, engineers, and manufacturers consistently prefer this-grade aluminum plate.

What is 5754 Aluminum Plate?

The 5754 aluminum plate is part of the 5000 series aluminum alloys (aluminum-magnesium), renowned for excellent corrosion resistance, especially in marine environments. The alloy is often processed in various tempers for specific mechanical and formability requirements. Typical tempers for 5754 include H22, H24, and H32, which define treatment strengths and characteristics involving cold working processes.

Chemical Composition and Standards

5754 aluminum alloy's performance comes from its precise chemical composition. The primary alloying element is magnesium, ranging between 3.0% to 3.5%, which imparts enhanced strength without compromising durability. Below is the standardized chemical composition as per EN 485 and ASTM B209 specifications commonly used worldwide:

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 3.0 – 3.5 |

| Manganese (Mn) | 0.5 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.2 |

| Titanium (Ti) | ≤ 0.15 |

Mechanical Properties & Temper Designations

The performance of the 5754 aluminum plate is influenced heavily by the temper, or hardening process, achieved mainly by cold working alongside appropriate heat treatments.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| O | 130 – 180 | 55 – 125 | ≥ 25 |

| H22 | 190 – 255 | 110 – 160 | ≥ 10 |

| H24 | 205 – 265 | 125 – 165 | 8 – 11 |

| H32 | 220 – 275 | 145 – 185 | 6 – 10 |

- O temper: Annealed state offering the best formability.

- H22, H24, H32: Various degrees of strength thanks to strain hardening.

Core Functions and Benefits

- Corrosion Resistance: Due to predominant magnesium levels, 5754 aluminum plates resist seawater, atmospheric corrosion, and industrial environments.

- Good Weldability: Compatibility with MIG, TIG, and spot welding facilitates manufacturing flexibility.

- Excellent Formability: Suitable for cold forming and complex shaping, especially in annealed (O) and partially hard states (H22).

- Lightweight Strength: Adequate mechanical properties while maintaining lightweight, contributing to fuel efficiency and ease of handling.

Main Applications

1. Marine Industry

Because of its outstanding resistance to corrosion caused by seawater and salty environments, 5754 aluminum plate is extensively used for the construction of ship hulls, decks, bulkheads, and other parts of boats and vessels. The alloy delivers durability and long lifecycle even without significant maintenance.

2. Transportation

In automotive and railway sectors, 5754 plates are preferred for body panels, chassis components, and cargo containers where strength-to-weight ratios are critical. Their weldability and formability also allow manufacturers to achieve sleek and aerodynamic designs.

3. Construction

Architects specify this alloy for roofing, cladding, bridge elements, and panels exposed to harsh environmental conditions, thanks to its longevity and resistance to corrosion or fading.

4. Pressure Vessels and Storage Tanks

Due to its excellent sealing and resistance to corrosion, 5754 plates are rolled and shaped into storage tanks, containers, and pressure vessels suitable for chemicals and hydraulic fluids.

Manufacturing and Implementation Standards

Companies adhering to producing 5754 aluminum plates below scenarios follow stringent industry standards:

- EN 485-2: Specifications for wrought aluminum sheets, strips, profiles, and plates for mechanical properties.

- ASTM B209 and B221: Specifications for aluminum and aluminum-alloy sheet and plate.

- ISO 6361: International specifications for aluminum alloys’ mechanical properties.

- Aluminium Association: Followed for temper designations and temper characterization.

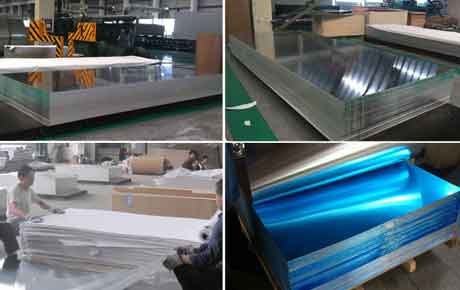

Custom orders can be fulfilled with thicknesses usually ranging from 2 mm to 250 mm, in variable lengths and widths. These plates often come surface-finished according to customer requirements, facilitating various industrial processes such as anodizing or painting.

The 5754 aluminum plate is undoubtedly a versatile material that marries excellent mechanical properties with outstanding corrosion resistance. Its significant magnesium content, suitable tempers, and flexible processing options make it ideal for demanding applications across users prioritizing longevity and performance, especially under challenging environmental conditions.

Whether you’re designing next-generation vehicles, corrosion-proof marine structures, or resilient industrial storage solutions, the 5754 aluminum plate offers reliability, durability, and efficiency that can meet your project’s toughest needs.

Invest in 5754 aluminum plates today to harness the unmatched potential of this high-performance alloy—your foundation to excellence in design and manufacturing.