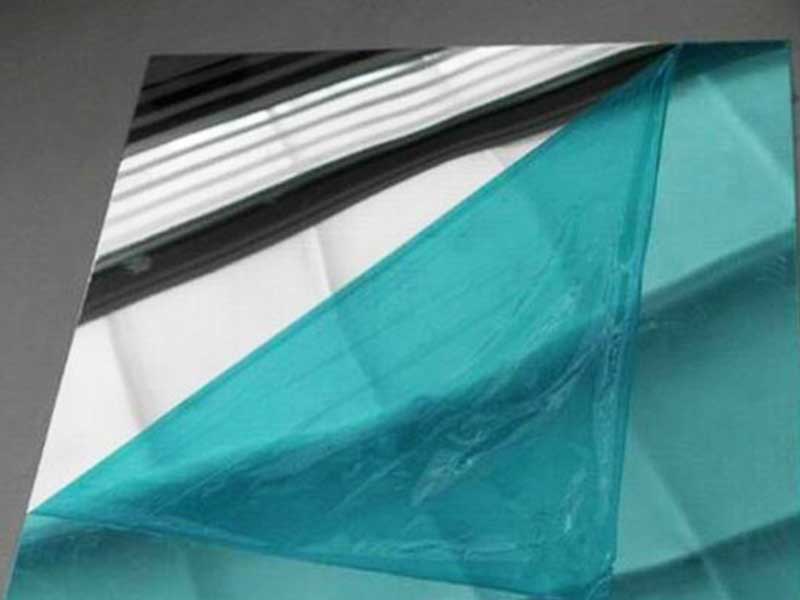

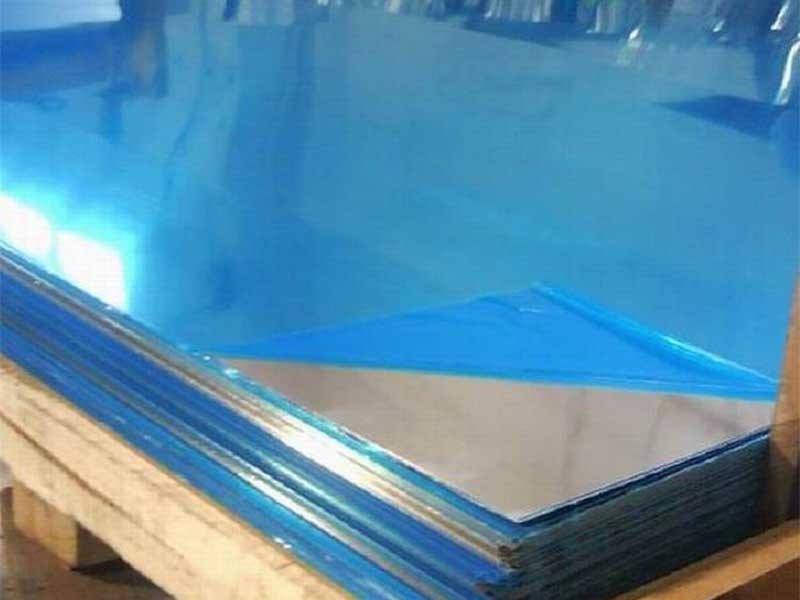

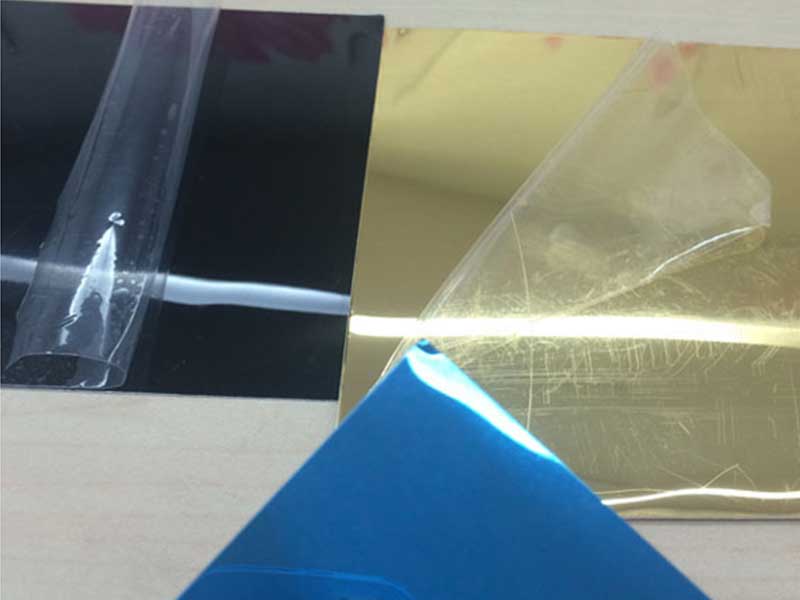

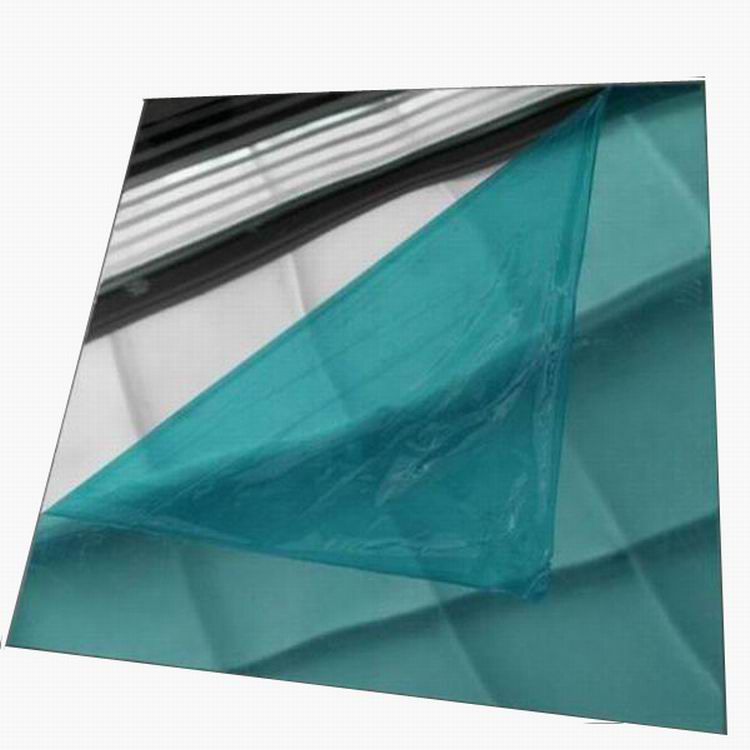

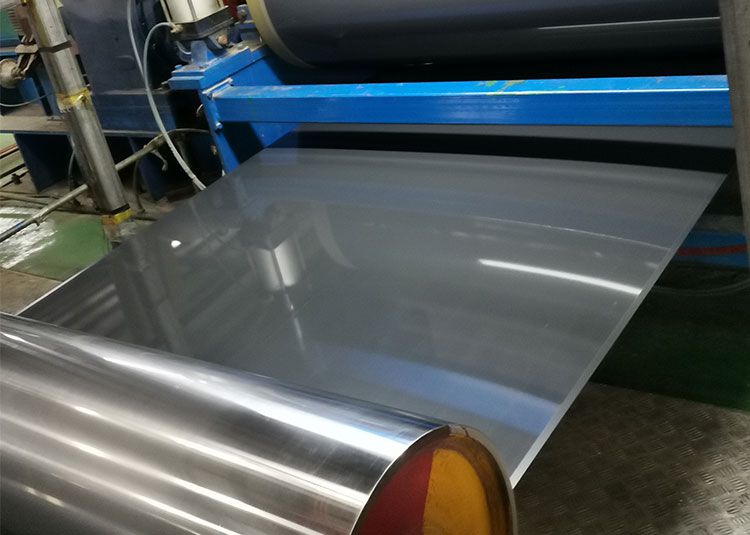

The Mirror Finish Alloy Metal Anodized 1050 is well-known in various industries today due to its unique properties and versatility. This aluminum alloy is characterized by its reflective surface and enhanced durability, making it ideal for decorative and functional applications.

Functions of Mirror Finish Alloy Metal Anodized 1050

High reflectivity, aesthetic appeal, and anti-corrosive properties are some of the functions of this anodized aluminum alloy. Here’s a breakdown of its primary functions:

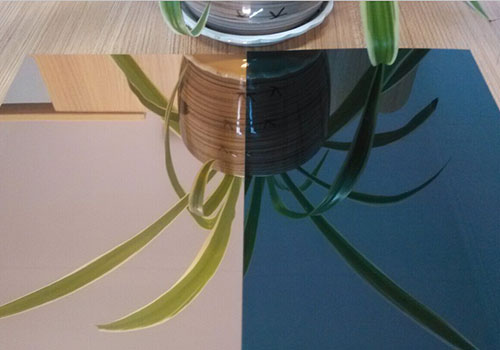

- Reflective Properties: The mirror finish achieves exceptional light reflection, making this alloy suitable for light fixtures and display cases.

- Corrosion Resistance: Anodizing forms a protective oxide layer, which prevents metal degradation.

- Aesthetic Appeal: The polished surface delivers a premium appearance, enhancing product attractiveness.

- Hygienic Properties: Aluminums are easy to clean and resist harboring bacteria, preferred for surfaces in medical and food industries.

Typical Applications

Reflective and durable, the 1050 anodized alloy finds use in numerous sectors, including:

- Architectural Projects: Used in facades and curtain walls for aesthetic and reflective capabilities.

- Lighting Industry: Commonly found in reflective surfaces of light fixtures and automotive headlights.

- Home Décor: Incorporated into furniture and ornamental trim.

- Signage: Used for neo-functional, reflective display signs.

Technical Details

To understand this product fully, it’s essential to explore its technical specifications, including composition and mechanical properties.

Chemical Composition

The chemical composition of the Mirror Finish Alloy Metal Anodized 1050 is critical. Here’s a table detailing its constituents:

| Element | Symbol | Percentage (%) |

|---|---|---|

| Aluminum | Al | Min 99.5 |

| Iron | Fe | Max 0.4 |

| Silicon | Si | Max 0.25 |

| Copper | Cu | Max 0.05 |

| Manganese | Mn | Max 0.05 |

| Magnesium | Mg | Max 0.05 |

| Zinc | Zn | Max 0.1 |

| Titanium | Ti | Max 0.1 |

Technical Specifications

Here are the technical parameters of the Mirror Finish Alloy Metal Anodized 1050:

| Property | Specified Value |

|---|---|

| Alloy Type | 1050 Aluminum |

| Tempering Condition | H14, H24 |

| Density | 2.710 g/cm³ |

| Thermal Conductivity | 235 W/M·K |

| Melting Point | 660°C |

| Yield Strength | 70 MPa |

| Tensile Strength | 110 MPa |

| Elongation at Break | 12% |

| Hardness | 60 - 70 Brinell |

| Coating Thickness | 10 - 25 µm |

Implementation Standards and Alloy Tempering Conditions

The alloy fulfulls several industry standards, ensuring quality and reliability in diverse applications:

- ASTM B221: Specifications for aluminum and aluminum allow extruded bars, rods, shapes, and wires.

- ASTM B580: Specification for anodic oxide coatings on aluminum.

- ISO 9001: Quality control standard relevant for manufacturers.

The tempering conditions typically involve one of the following forms of processing:

| Temper Condition | Description |

|---|---|

| H14 | Strain-hardened, low assembly use |

| H24 | Strain-hardened, suitable for applications requiring mobility |

Advantages of Using Mirror Finish Alloy Metal Anodized 1050

Here are the advantages of selecting this mirror finish alloy for various selections:

- Sustainability: Recyclable and less energy-consuming in the anodizing process.

- Versatility: Adaptable for multiple applications, adding functionality and durability to projects.

- Enhanced Appearance: Provides a sleek contemporary look, enhancing aesthetic dimension considerably.