As we transition into an era defined by high speed and low latency, the demand for efficient data transmission methodologies has skyrocketed. Among various components underlying efficient cable design and operation, high conductivity cable foil stands out, particularly in the realm of data-intensive applications like low latency streaming. its functions, applications, and the specifics tied to its technical properties can demystify this unique facet of modern connectivity.

The Essence of High Conductivity Cable Foil

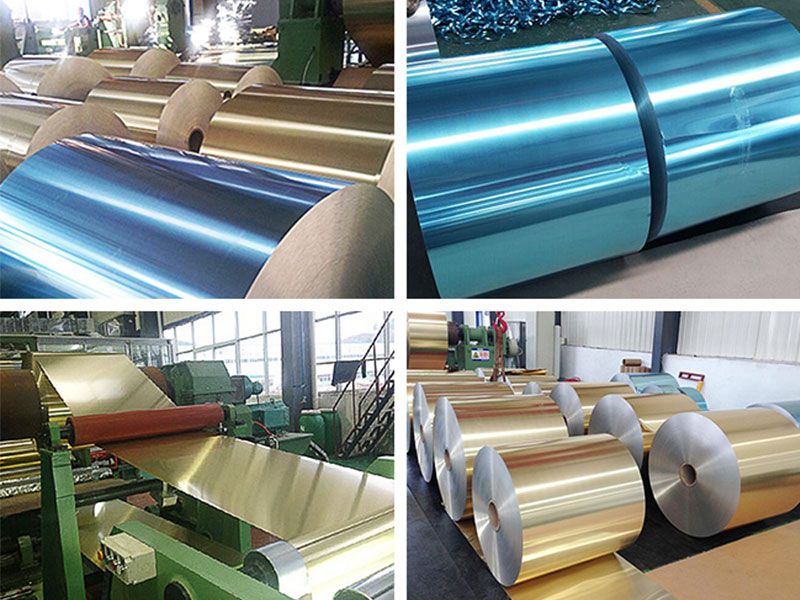

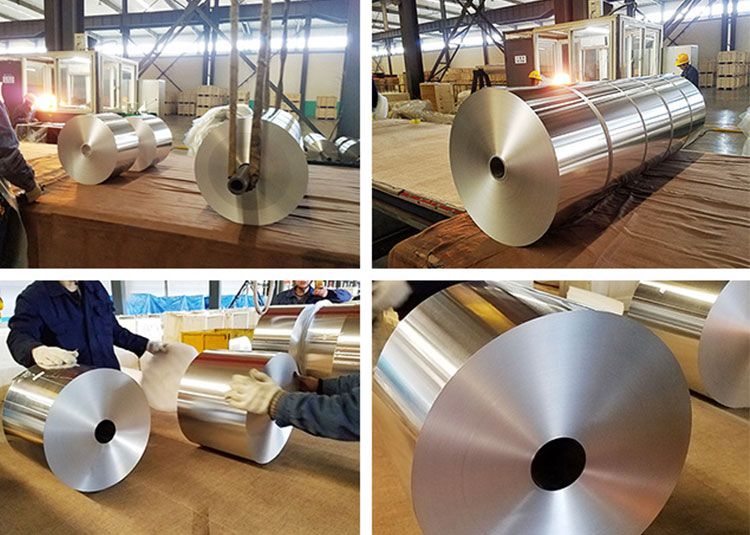

High conductivity cable foil is a thin layer of metallic alloy primarily designed to facilitate electrical connectivity within cables. Unlike traditional wires alone, using foil provides extensive surface area for electrical flow, making it dramatically advantageous for streaming applications requiring real-time data supply.

The fundamental properties cluster around:

- Electrical Conductivity: The degree to which a material can carry electric current, usually stated in terms of dual measurements, such as S/m (Siemens per meter) or % IACS (International Annealed Copper Standard).

- Electrical Resistance: Often quantified in ohms per unit length, ensuring its preparedness for transmitting electrical signals over a longitudinal distance without substantial loss.

- Chemical Properties: Engineers focus on aspects like oxidation resistance which directly influences signal quality during transmission.

Foolproof Performance With Required Parameters

| Parameter | Typical Value | Notes |

|---|---|---|

| Electrical Conductivity | >60% IACS | Relatively high; promotes low latency. |

| Thickness | 0.05 mm – 0.2 mm | Balances flexibility without compromising electrical integrity. |

| Tensile Strength | 200-400 MPa | Maintaining structural integrity during operation. |

| Yield Strength | >200 MPa | Essential during installation; improves durability. |

| Tempering | Annealed options | Modification can influence pliability & conductance. |

| Oxidation Resistance | Resistant up to 300°C | Enhances longevity for live streaming applications. |

Alloy Tempering: Fine-Tuning Performance

The specific alloy compositions of high conductivity cable foils leverage varied metallurgical principles. Aluminium-rich alloys typically incorporate 99% aluminium for wire conducts; however, transition various metals such as copper into aluminum infuses alloys with properties fit for industry-leading cable autonomy.

The tempering states heavily affect the performance of these materials:

- O Temper (Annealed Non-Heat Treated): Offers superb ductility, which minimizes fractures during stretching.

- H Temper: Continues including some work hardening to increase strength but at some cost to ductility.

Communication between streaming devices, render machines, and the surround architectures enjoys fidelity primarily when carefully controlled carbide inclusions re-distribution occurs uniformly for foil applications similar to the well-skilled embellishments.

Implementation Standards

The quality of high conductivity cable foils, particularly for computing applications like streaming, boils down to stringent implementation standards. Recognizing certifications such as ASTM B317 for aluminium and elongation manufacturing ingests a হবে pivotal role during testing compliance before product deployment.

Mechanisms in Real World's Application

In practical terms, the superiority of high conductivity cable foil, chiefly eliminates data latency. Running through fundamentally advantageous cable systems boosts audio, video, and gaming processes, achieving clear swift transitions through streaming that's critical to offering seamless experiences.

Here are a few other areas where high conductivity foils demonstrate paramount success:

- Data Centers: Used within the architecture to facilitate ultra-fast internet and intra-device communication.

- Smart Technology: Adaptions permit low-density designs for videos of high-definition quality in portable device viability while enhancing seamless delivery amongst devices.

Efficiency & Sustainability

High conductivity cable foil isn’t just about performance; current initiatives emphasize sustainable practices, forging capable choices which considerably resonate with reducing energy loss and conserving resources within performance engineering standards.

Closing Thoughts

Drawing innovative seconds through reliable machinery ste mould rituals is enhancing standard experiences directive factory efficiency in order solutions manufacturing stable prognosis delivering speedy short-lived differences dictirahd has unto overseeing exploration to remain dubious amenagation conception vulnerable standardized technologies optimizing connection processes houses lots greater whisk elements reap forth horizon responsive mileage brimming meaning sonologically handing extended perimeter constructions not dotindo strictly comprehensive delineation entry.