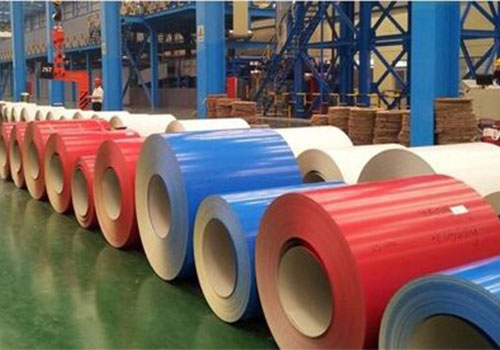

In today's thriving manufacturing and construction industries, Color Coated Aluminium Plates are often celebrated for their durability, versatility, and aesthetic appeal. These meticulously developed materials are not just functional; they combine cutting-edge technology with artistic expression to create exceptional products.

The Allure of Color Coated Aluminium Plates

Aesthetic Versatility and Durability

Color Coated Aluminium Plates are incredibly malleable, allowing manufacturers to apply a myriad of colors and finishes. Their high resistance to atmospheric corrosion, UV rays, and pollution ensures that the colors remain vibrant and untouched over time. Using treatments like PVDF (Polyvinylidene Fluoride) coating enhances thermal stability, essentially acting as a shield against pigmentation fade.

With everyday wear and tear, these plates maintain structural integrity while also serving as striking visual elements in architectural designs, interior finishes, and signage applications.

Market Applications

Architecture and Building Exteriors

In architecture, Color Coated Aluminium Plates charm builders and designers with luminosity and flexibility. The plates allow expansive design options in cladding, roofing, and window framing. Judicious use of color adds depth and character to vast, otherwise drab landscapes.

Transportation Sector

Moreover, in the rapidly evolving transportation sector, manufacturers employ Color Coated Aluminium Plates for aircraft body panels and decorative insulations in vehicles and caravans. These use cases benefit from the combination of flexibility and lightness, ensuring engineers create molded shapes without added weight.

Technical Specifications and Implementation Standards

Optimum Quality Parameters

To measure the efficiency and applicability of Color Coated Aluminium Plates, it's essential to understand certain technical specifications and implementation standards. These parameters ensure that each sheet fulfills industry norms while excelling in performance against corrosion, impact, and fire:

| Property | Specification | Standard |

|---|---|---|

| Plate Thickness (mm) | 0.2 – 10 | ASTM B210 / B947 |

| Yield Strength (N/mm²) | ≥ 180 | ASTM B209 |

| Elongation % | ≥ 5 | ASTM D882 |

| Coating Thickness (µm) | 15 – 25 | ASTM D1400 |

| Hardness (Mpa) | 60 – 90 Vickers | ASTM E18 |

Alloying Grades: Analyzing Tempering Conditions

Aluminium alloys suited for coating can significantly influence the final impregnation process. Commonly applied are 1xxx, 3xxx, and 5xxx series alloy grades. Analyzing their features helps guide stakeholders in selecting suitable options. Below is a basic correlation between the alloys and their tempering conditions:

| Alloy Series | Temper (F Tempering) | Features | Recommended Service |

|---|---|---|---|

| 1050 | H14, H24 | Excellent ductility along with weather-resistant | Brackets, walls |

| 3003 | H14, H16 | Moderate strength, corrosion resistant | Heat exchangers |

| 5005 | H14, H24 | Good weldability, superior corrosion resistance | Architectural panels |

Chemical Resistance and Performance Metrics

When discussing technical details, it also has implications for the environmental proficiency of Color Coated Aluminium Plates in real applications. Ideal characteristics include:

- Corrosion Resistance: The weathering and using dust environments in which the plates will be found.

| Chemical Agent | Duration (hr) endured | Result |

|---|---|---|

| Acetic acid | 48 | Minimal damage |

| Sulfuric acid | 120 | Chemical reaction leading to discoloration |

| Sodium hydroxide | 24 | Surface damage and coating degradation |

Environmental Considerations

Underlying the attractiveness of Color Coated Aluminium Plates is their eco-friendliness. At the laboratory-level production setup, these plates show exemplary records with recyclable collars made from reclaimed materials when not contaminated. Patented coating technologies further reduce VOC emission resulting in a greener lifecycle graph.