ASTM B209 Alloy 6061 T6 Aluminium Sheet: A Technical Story Told From The Inside Out

When engineers specify “ASTM B209 6061 T6 aluminium sheet,” they are not just picking a material; they are defining how stress will flow through a structure, how heat will dissipate, and how the product will behave ten years down the line. To understand this alloy correctly, it helps to stop thinking of it as a simple sheet and start thinking of it as a precisely tuned internal micro‑engine of aluminum, magnesium, and silicon.

What ASTM B209 Really Means For 6061 T6 Sheet

ASTM B209 is not just a label; it is the rulebook that defines how flat‑rolled aluminium sheet and plate must behave and how their properties are verified. When 6061 T6 sheet is ordered to ASTM B209, three dimensions of performance are being locked in simultaneously:

- Dimensional discipline: thickness, width, length, flatness, and edge condition are strictly controlled.

- Mechanical reliability: specified minimum tensile strength, yield strength, and elongation, dependent on thickness range.

- Metallurgical cleanliness: limits on defects, internal soundness, and surface quality that matter much more during machining, welding, or anodizing than many realize.

From the inside-out perspective, ASTM B209 is a filter: it screens out inconsistent microstructures, uncontrolled grain sizes, and unpredictable heat-treat history. Material that fails to achieve consistent precipitation of Mg2Si, uniform hardness across the sheet, or clean rolling texture will typically fail somewhere against B209’s mechanical or dimensional requirements.

The Metallurgical Engine: Alloy 6061 As A Precipitation-Hardened System

Alloy 6061 belongs to the 6xxx series aluminum–magnesium–silicon (Al‑Mg‑Si) system, built around precipitation hardening. Its strength does not come simply from being “aluminum with additives” but from deliberately creating, dissolving, and re‑precipitating secondary phases inside the solid solution.

In 6061 T6, the performance is driven by:

- Solid solution hardening from Mg and Si dissolved in the aluminum matrix.

- Controlled grain size and texture set during rolling and final heat treatment.

Temper T6: A Time–Temperature Story Written In The Alloy

The “T6” temper is not just a code; it is a documented thermal history. The sheet has been:

- Solution heat treated

- Quenched

- Artificially aged to a substantially stable condition

From an internal view, these steps do the following:

Solution heat treatment

At elevated temperature, the Mg and Si dissolve into the aluminum matrix, forming a supersaturated solid solution. This phase is like a “reset,” erasing previous precipitate structures and strain histories.

Quenching

Rapid cooling “freezes in” the supersaturated state. Solute atoms do not have time to diffuse and precipitate during cooling, so they remain uniformly distributed, primed for controlled precipitation during aging.

Artificial aging

The sheet is held at an intermediate temperature where atomic diffusion proceeds at a controlled rate. Fine, coherent, and semi‑coherent Mg2Si precipitates form. Their size, spacing, and distribution are what define the “T6” strength level.

For 6061 sheet, this usually translates to:

- High tensile strength with predictable, repeatable yield

- Good balance of stiffness and formability for bending and moderate forming operations

- Stable mechanical properties under typical service temperatures

Technical Parameters Of ASTM B209 6061 T6 Aluminium Sheet

From a design point of view, several parameters matter: mechanical, physical, dimensional, and surface. From the inside-out approach, each parameter is a visible shadow of an invisible microstructure.

Typical mechanical properties for 6061 T6 sheet (values can vary slightly with thickness and product form, but under ASTM B209 they must meet minimums):

- Tensile strength: approximately 260–310 MPa

- Yield strength (0.2% offset): approximately 240–275 MPa

- Elongation: typically 8–12% in 2 inches, depending on thickness

- Brinell hardness (HBW 10/500): around 90–100 HB

Physical parameters:

- Density: about 2.70 g/cm³

- Modulus of elasticity: around 69 GPa

- Coefficient of thermal expansion (20–100 °C): about 23–24 µm/m·°C

- Thermal conductivity: roughly 167 W/m·K

- Electrical conductivity: about 40% IACS (approximate, temper dependent)

Dimensional and flatness controls under ASTM B209 include:

- Tight tolerance bands on thickness across the sheet width

- Controlled crown (difference in thickness between center and edges)

- Flatness parameters that directly influence laser cutting, CNC routing, and tight‑tolerance assembly

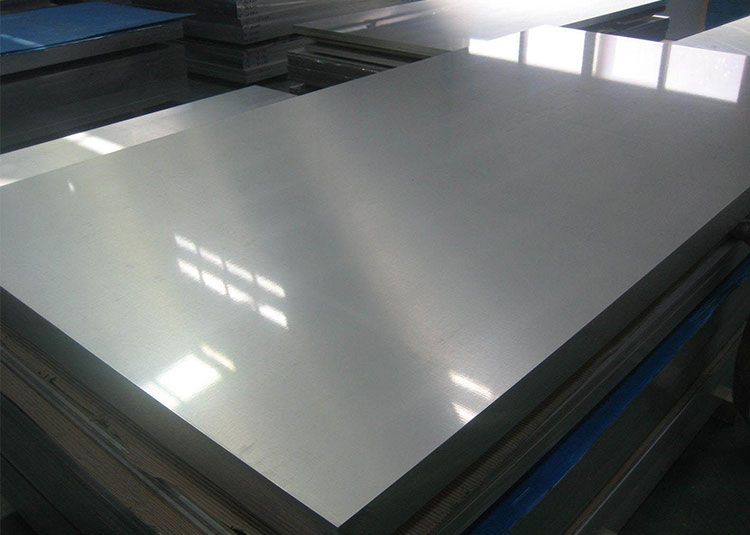

When the sheet lies flat on a surface with minimal waves, that is not a random outcome; it is the signature of well‑controlled rolling reduction schedules, tension leveling, and the absence of residual stress concentrations.

Chemical Composition Of 6061 Aluminium Alloy

The chemistry of 6061 is carefully balanced. Each element plays a specific structural role within the matrix and the precipitate phases.

Typical chemical composition of 6061 aluminium alloy:

| Element | Content (wt%) |

|---|---|

| Magnesium (Mg) | 0.8 – 1.2 |

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 – 0.40 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Manganese (Mn) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Aluminium (Al) | Balance |

From a microstructural viewpoint:

- Magnesium and silicon combine to form Mg2Si, the main strengthening phase. Their ratio is critical; excess of one or the other can drive unwanted phases that weaken or embrittle the material.

- Copper provides additional strength but must be controlled to avoid sacrificing corrosion resistance.

- Chromium stabilizes grain structure, suppresses grain growth during heat treatment, and improves toughness consistency through thickness.

The Role Of Standards: ASTM B209, Tempers, And Beyond

ASTM B209 does more than set dimensions and minimum strengths. It implicitly ratifies the heat treatment, rolling practice, and metallurgical controls behind each sheet.

In practical terms, ordering “ASTM B209 6061 T6 aluminium sheet” means:

- Heat treatment and temper must correlate to recognized T6 practice

- Mechanical properties must meet or exceed published minimum values

- The producer’s process is stable enough that each coil or plate can pass periodic and lot‑based testing

Different tempers of 6061 tell different stories:

- O temper: fully annealed, softer, with low internal stress and high formability

- T4 temper: solution heat‑treated and naturally aged to a stable condition, lower strength than T6 but better formability and crashworthiness

- T6 temper: solution heat‑treated and artificially aged for maximum or near‑maximum strength in many thickness ranges

- T651 / T6511 (more relevant to plate/extrusion): T6 with stress relief by stretching, reducing residual stress and distortion during machining

Surface, Anodizing, And Corrosion: How Microstructure Moves To The Surface

6061 T6 is widely known as a good anodizing alloy. The reasons are hidden in both chemistry and microstructure.

The Al‑Mg‑Si system supports:

- Uniform anodic film growth with consistent pore structure

- Good adhesion of anodic oxide due to clean, refined grain boundaries

- Plausible decorative finishes, though 6061 is not as purely cosmetic as some 5xxx or special anodizing alloys

Under ASTM B209, surface quality requirements limit deep scratches, inclusions, and lamination defects. On an anodized product, these would become highly visible. From the microstructural angle, internal inclusions, coarse intermetallics, and segregated bands all tend to telegraph to the anodized surface through localized color variation, pitting, or micro‑roughness.

Corrosion behavior follows a similar pattern:

- Balanced Mg and Si contents avoid galvanically aggressive second phases.

- Proper quench and age keep precipitates fine and well distributed, preventing continuous networks along grain boundaries which can promote intergranular corrosion.

- Excess copper or poor thermal history can create microscopic galvanic cells; hence chemistry and process control are as critical as nominal alloy designation.

Design Use Cases: Why 6061 T6 Sheet Behaves So Well In Real Structures

The popularity of 6061 T6 sheet in structural, transportation, marine, and mechanical applications is not just due to “medium strength and good corrosion resistance.” It is the particular blend of internal order and external workability.

Typical use cases include:

- Aircraft fittings and non‑primary sheet components

- Automotive panels, suspensions, brackets, and structural skins

- Marine and offshore components where weight reduction and corrosion resistance are critical

- Frames, enclosures, and panels in industrial machinery

- CNC‑machined sheet parts, where flatness and dimensional stability after machining are essential

In each application, the same internal factors matter:

- Precipitate strength controls the load-carrying capacity

- Residual stress and grain texture control distortion after cutting or machining

- Surface integrity and cleanliness control anodizing and painting quality

Instead of thinking of 6061 T6 simply as “strong enough and light enough,” it is more accurate to see it as “microstructurally tuned to be predictable” – and predictability under ASTM B209 is what design engineers actually buy.

Balancing Parameters For Project Success

Choosing ASTM B209 6061 T6 aluminium sheet is a balancing act between many interacting parameters:

- Thickness and flatness tolerances tied directly to forming, laser cutting, or precision machining tasks

- Mechanical profile (strength and elongation) adjusted via temper and heat‑treat control

- Surface and internal cleanliness aligned with downstream finishing, especially anodizing and powder coating

- Alloy chemistry fine‑tuned to deliver corrosion resistance in the specific environment, from inland industrial to marine atmospheres

From the internal metallurgical point of view, every visible parameter is a downstream consequence of how atoms diffused, how grains grew, how precipitates formed, and how rolling passes were scheduled. ASTM B209 serves as the bridge, ensuring that the silent internal story of the metal becomes a measurable, dependable external performance in your design.