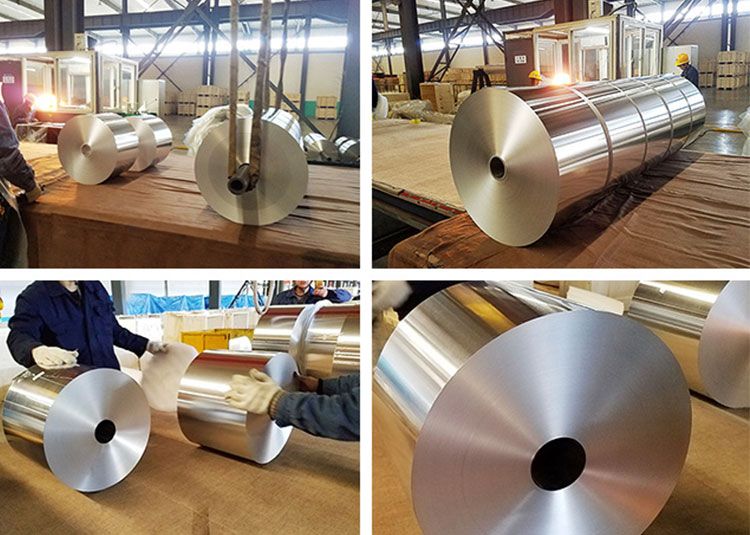

Aluminum coils for medicine are high-grade aluminum materials processed into thin, durable sheets coiled for ease of transportation and customization. These coils are designed to meet stringent pharmaceutical industry standards, providing superior barrier properties against moisture, oxygen, light, and microbial contamination.

Features

| Feature | Description |

|---|---|

| High Purity Aluminium | Typically 99.0% or higher aluminum content to ensure safety and avoid contaminations. |

| Excellent Barrier Properties | Protects medicines from exposure to moisture, oxygen, and UV radiation, preserving drug potency. |

| Corrosion Resistant | Inherently resistant to oxidation and corrosion, avoiding reaction with medicine ingredients. |

| Malleability & Formability | Enables easy processing into various pharmaceutical packaging formats like blister packs and foil wraps. |

| Non-toxic & Safe | Meets pharmaceutical-grade non-toxicity standards, especially important where direct contact with medicinal products is expected. |

| Lightweight | Reduces overall weight, facilitating handling and reducing logistic costs. |

| Heat Reflectivity | Helps insulate and protect temperature-sensitive medicines during transport and storage. |

Chemical Composition and Standards

Medical aluminum coils must fulfill strict chemical and quality requirements for use in the pharmaceutical industry. Common aluminum alloy grades used in medicine packaging and their approximate chemical compositions are listed below:

| Alloy Grade | Al (%) | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Others (%) | Typical Applications |

|---|---|---|---|---|---|---|---|---|---|

| Al 1050 | 99.5 | 0.25 | 0.40 | 0.05 | 0.05 | 0.03 | - | 0.03 | High purity for foil wraps and blister pack bases. |

| Al 1235 | 99.3 | 0.30 | 0.50 | 0.05 | 0.05 | 0.03 | - | 0.07 | Drawn and easily formed pharma packaging foil. |

| Al 8011 | 97.0-99.0 | 1.20-1.80 | 1.00-1.50 | 0.05-0.20 | 0.50-1.00 | - | - | 0.30 creatively | Common in pharmaceutical foil laminates requiring enhanced strength. |

Note: The above compositions are illustrative. Exact makeup may vary by vendor certificate and regulatory requirements.

Typical Pharmaceutical Applications

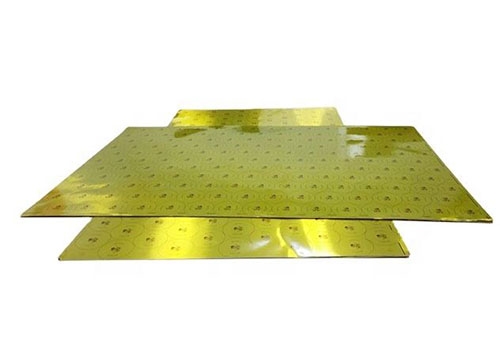

Blister PacksAluminum coils are converted into thin foils for forming blister packs used extensively for tablets, capsules, and vaccines. Their barrier properties shield medicines from humidity, contamination and mechanical shocks while allowing easy peel or push-through functionality for patients.

Strip Foil ContainersUsed for syringes, ampoules, and small-size medical vials, aluminum coils help form flexible and secure sealing strips to maintain sterility and integrity.

Cold Chain PackagingDue to aluminum's high thermal reflectivity and lightweight nature, coils for cold chain pharmaceutical packaging assist in protecting temperature-sensitive medicines like insulin or biologics throughout transportation and storage.

Medical Device WrappingAluminum coils are used in packaging critical medical devices, surgical tools, and implants to provide contamination-free wrappers with anti-corrosion features and ease of sterilization.

Pharmaceutical Tubing and CapsWith good formability, coils are fabricated into tubes and caps contributing to sealed, contamination-proof medicine storage.

Why Choose Aluminum Coil for Medicine Packaging?

Compliance with International Pharmacopoeia StandardsOur aluminum coils meet FDA, EMA, and WHO raw material standards, ensuring high compatibility for use in direct medicine contact and packaging.

Superior Quality and ConsistencyRolling and annealing are optimized for consistent thickness, purity, and surface finish crucial in precision pharmaceutical manufacturing environments.

Customized SolutionsThickness variability from 8µm to 100µm, width adjustments, and optimized mechanical properties for specific packaging requirements.