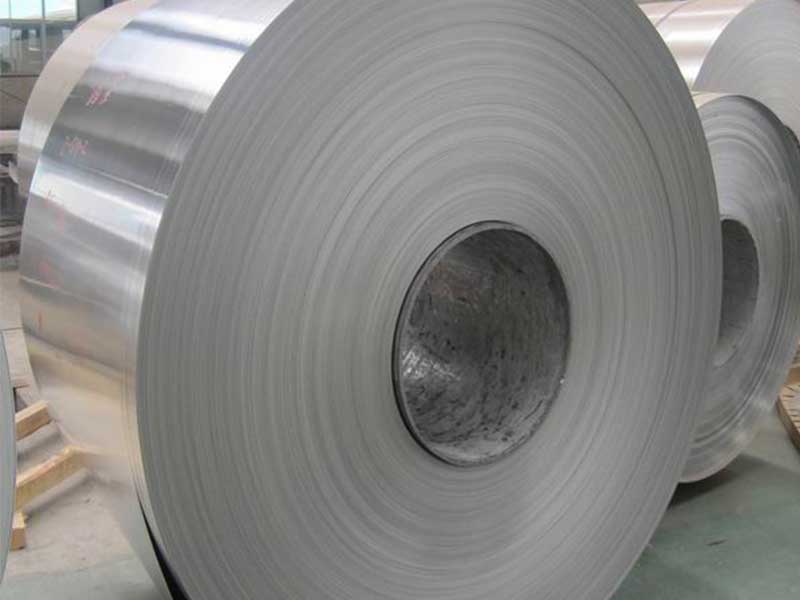

1050-O Aluminium Strips

10/15 2025 Leo

Features of 1050-O Aluminium Strips

- High Aluminum Purity (≥ 99.5%): Offers outstanding corrosion resistance, especially in atmospheric and chemical exposure environments.

- Excellent Formability: Due to annealed condition "O", it exhibits the highest ductility among aluminum alloys, permitting easy bending, shaping, and forming without cracking.

- Good Electrical Conductivity: Ideal for electrical applications that require excellent conductivity.

- Superior Thermal Conductivity: Facilitates rapid heat dissipation which is useful in heat exchangers.

- Non-toxic and Environmentally Friendly: Suitable for food and pharmaceutical industry applications.

- Lightweight & Non-magnetic: Contributes to weight reduction in finished products and is suitable where non-magnetic properties are essential.

Chemical Composition of 1050 Aluminium Alloy

| Element | Typical Content (%) | Maximum Allowable (%) |

|---|

| Aluminum (Al) | 99.50 | — |

| Copper (Cu) | — | 0.05 |

| Iron (Fe) | — | 0.40 |

| Manganese (Mn) | — | 0.05 |

| Silicon (Si) | — | 0.25 |

| Zinc (Zn) | — | 0.10 |

| Titanium (Ti) | — | 0.03 |

| Others (each) | — | 0.03 |

| Others (total) | — | 0.10 |

Note: Values reflect typical alloy limits to ensure consistent purity and performance.

Mechanical Properties of 1050-O Aluminium Strip

| Property | Value | Unit | Test Standard |

|---|

| Tensile Strength | 40 – 60 | MPa | ASTM B209 |

| Yield Strength (0.2% offset) | ≥ 20 | MPa | ASTM B209 |

| Elongation (A50 mm) | ≥ 35 | % | ASTM E8 |

| Hardness (Brinell, typical) | 15 – 30 | HB | ASTM E10 |

| Density | 2.71 | g/cm³ | ASTM B209 |

| Thermal Conductivity | 220 | W/m·K | |

| Electrical Conductivity | 59 | % IACS | |

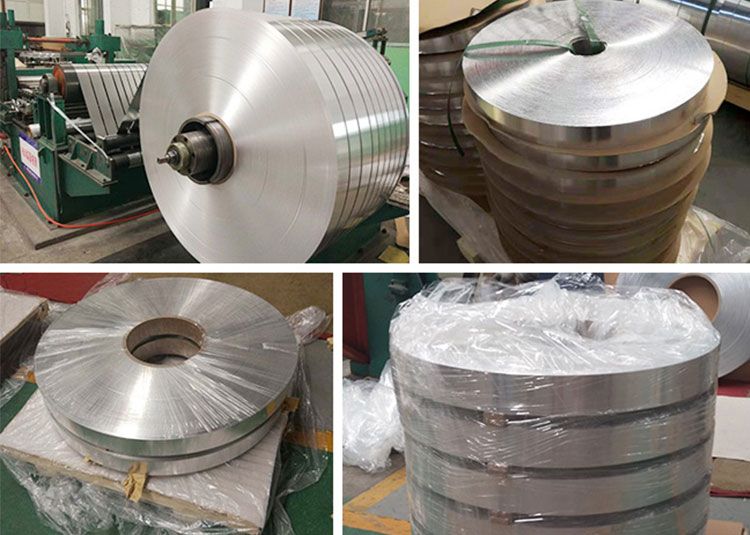

Technical Specifications

| Parameter | Specification/Range | Unit |

|---|

| Thickness Range | 0.2 – 6.0 | mm |

| Width Range | 10 – 1500 | mm |

| Length | Coil or Cut-to-Length | mm |

| Surface Finish | Mill Finish, Bright Finish | — |

| Temper | O (Annealed - Soft) | — |

| Flatness | Meet customer or standard requirement | — |

| Straightness | ≤ 1.0 | mm/m |

Performance Highlights

- Corrosion Resistance: Weight loss due to corrosion remains minimal under atmospheric exposure, acidic, or mildly alkaline environments.

- Fabrication Capability: Excellent compatibility with deep drawing, bending, rolling, and welding operations, especially TIG and MIG.

- Recyclability: Fully recyclable with no loss of physical or chemical properties, contributing to sustainable manufacturing goals.

- Non-magnetic: Useful in precision physics applications or electrical shielding that disallows magnetic interference.

- Surface Treatment: Compatible for anodizing, chromate conversion, or painting to tailor applications further.

Typical Applications

| Industry | Applications |

|---|

| Electrical | Busbars, conductors, transformers, capacitors |

| Food & Beverage | Packaging, wrapping, and storing food where hygiene is crucial |

| Architectural | Ceiling panels, wall coverings, ventilation ducts |

| Transportation | Automotive heat reflectors and cosmetic trim |

| Chemical Processing | Corrosion-resistant tanks, piping liners |

| HVAC Systems | Heat exchangers and ventilation devices |

| Packaging | Flexible lids, foil inserts |

| Consumer Products | Household utensils and kitchenware |

| Benefit | Description |

|---|

| Corrosion resistance | Excellent environmental and chemical corrosion resistance enables longevity |

| Flexibility & machinability | Soft annealed temper supports complex forming demands with pretty low deficiency risks investigations |

| High Electrical Conductivity | Low resistivity facilitating efficient electrical systems |

| Lightweight | Lower densities enable energy-efficient requirements such as fuel cost saving parts |

| Safety | Non-toxic material is perfect for packaging and appliances linked with human habitual use. |

| Cost-Effective | One of the cost-effective aluminum alloys common in diverse production settings |

1050

https://www.aluminum-sheet-metal.com/a/1050-o-aluminium-strips.html

Related Products

Related Blog