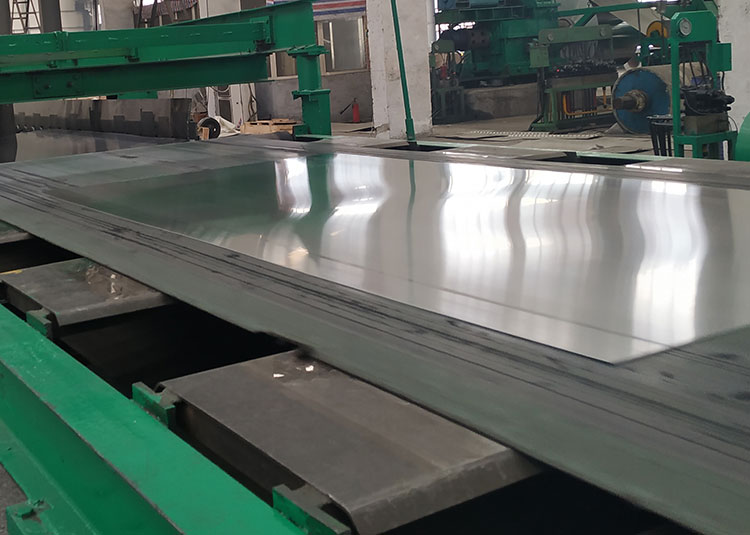

Aluminium plate, as the name suggests is made of aluminium or aluminium alloy material made of plate. Or by the flat aluminium embryo by heating, rolling and straightening or solid solution aging heat and other processes made of plate aluminium products.

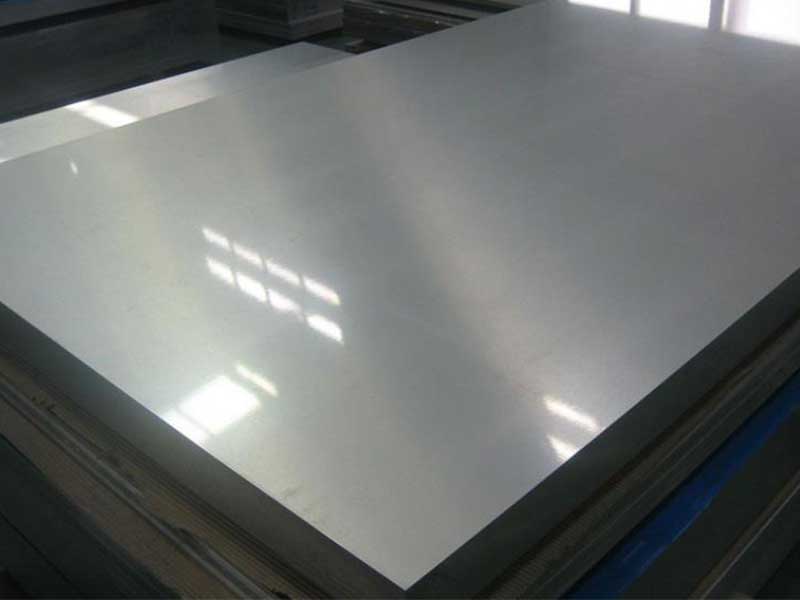

Aluminium used in the building, including single-layer aluminium, composite aluminium and other materials, generally refers to the single-layer aluminium (also called a single aluminium or pure aluminium), used in architectural decoration works, in recent years in the aluminium curtain wall single-layer aluminium The more common. Aluminium curtain wall is also a form of curtain wall, simply made of aluminium instead of glass curtain wall, aluminium curtain wall used for wall protection and non-lighting walls. Such as the Guangzhou World Trade Center, on the use of the Southwest aluminium processing plant plate processing different arc of aluminium nearly 150 tons, the surface using electrostatic spraying. Foreign aluminium curtain wall has been selected single-layer aluminium. Single-layer aluminium plate is generally made of pure aluminium. Aluminium plate thickness of 3mm, in order to strengthen the aluminium plate surface strength, in the back of the aluminium plate, must be installed ribs (existing manufacturers uneasy), ribs made of thick aluminium, first with a flash welder to a screw cap Welded on the back of the aluminium plate and then put the ribs into the screws into the screws, fixed with screws.

China in order to reduce the weight of aluminium, aluminium plate strength, we use aluminium alloy plate, often use No. 21 rust-proof aluminium code LF21 pressed aluminium plate for the curtain wall aluminium. Aluminium plate thickness from the original 3mm reduced to 2.5mm, the strength of the alloy than pure aluminium about twice. Reinforcement with LF21 aluminium belt, the width of aluminium tape thickness depends on the aluminium plate, generally thick 2-2.5mm, width 10-25mm. Aluminium curtain wall of the back of the aluminium Why should the installation of stiffeners, is the case of positive and negative pressure in the outside, the aluminium will not be a depression, two will not bulge, so to avoid the aluminium wall and repeated vibration inside and outside the vibration sound. If you need insulation, can be inside the aluminium plate, placed rock wool, slag cotton or foam treatment.

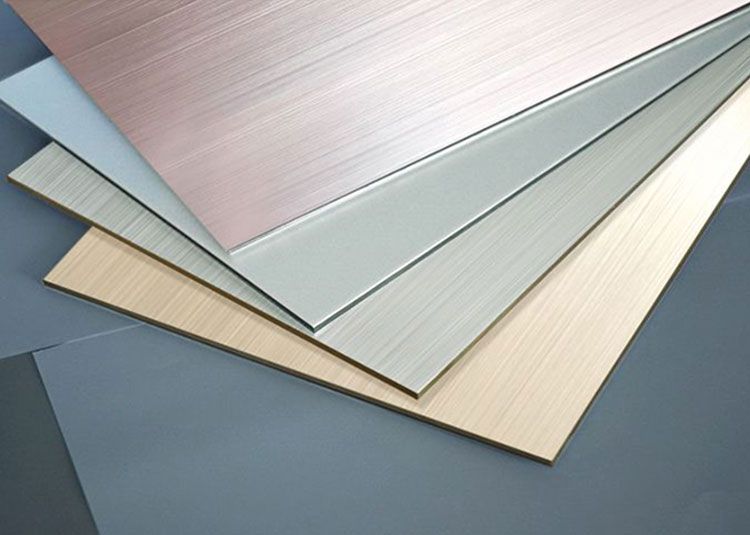

China’s first production of aluminium curtain wall aluminium manufacturers, Chongqing Southwest aluminium deep processing plate, the plate for the military manufacturers, the production of aluminium plate width can reach 2.8 meters. Curtain wall aluminium surface treatment, can be divided into two methods, one is anodized, the other is electrostatic spraying. Anodized oxide film is generally more than 12μ, the color is only bronze and white two, color monotonous, more serious shortcomings is the color of each piece of aluminium plate color varies, many pieces of curtain wall panels together to form a curtain wall overall effect Very ugly. This shortcoming can be said that can not be eliminated, not the production technology, but because the aluminium plate is not a batch number, chemical composition, there are small differences, coupled with oxidation when the electrolyte current density and other factors can not be exactly the same, so oxidation of the color of how many are different, leaflets may not be obvious, if all together is very obvious. So the aluminium plate curtain wall aluminium surface treatment, must not be used anodized.